For semiconductor production, there is an important process to make high-quality electronic device, Chemical-Mechanical Polishing (CMP). Process for CMP provides a conditioned silica based abrading surface for Battery pack welding machine use in performing chemical mechanical planarization comprised of a slurry having a first portion disposed in a semiconductor processing apparatus used for containing a silicon wafer.

Chemical–mechanical polishing (CMP) is an indispensable routine in the manufacturing process of chip. It serves to eliminate any defects present in the wafer surface, such as scratches or rough areas, which might lead to Film to Film Die Sorter defective product performance. By dissolving unwanted material with a mix of chemicals and polishing the surface with mechanical forces, CMP makes wafers smooth and flat, in preparation of the next steps in the manufacturing process.

CMP has transformed the manner in which chips are made and has enabled chip manufacturers to produce high-quality wafers. By using CMP in their production line, businesses including Minder-HighTech have been able to guarantee higher quality wafers, and Battery welder consequently more reliable and efficient electronic products. CMP also enhances the wafer planarity and uniformity allowing us to see the wafer circuits and components very clearly.

There are some important steps in the CMP for surface planarity. The wafer is first set on a polishing pad, and a slurry including chemicals and abrasives is provided to the surface of the wafer. Then, a polishing head applies pressure to the wafer, going back and forth across the surface to eliminate imperfections. The Die attach slurry sweeps the excess material from the wafer as it is polished, resulting in a level and uniform surface. Finally, the wafer is rinsed and dried, prepared for the subsequent process step.

And as shows no sign of abating, neither does the evolution of CMP systems for next generation chip structures. Businesses such as Minder-Hightech are continually researching new and creative techniques for CMP process design, as the semiconductor industry is always developing new products that Battery wire bonder place aggressive Film Planarity requirements on the CMP process. With new materials and better polishing methods, CMP technology is enabling to build smaller, faster, and more efficient electronic devices.

Minder Hightech is CMP process by a group of high educated experts, skilled engineers and staff, who have impressive professional skills and expertise. Our brand's products have been introduced to many industrialized countries around the world to help customers increase efficiency, reduce costs, and increase product quality.

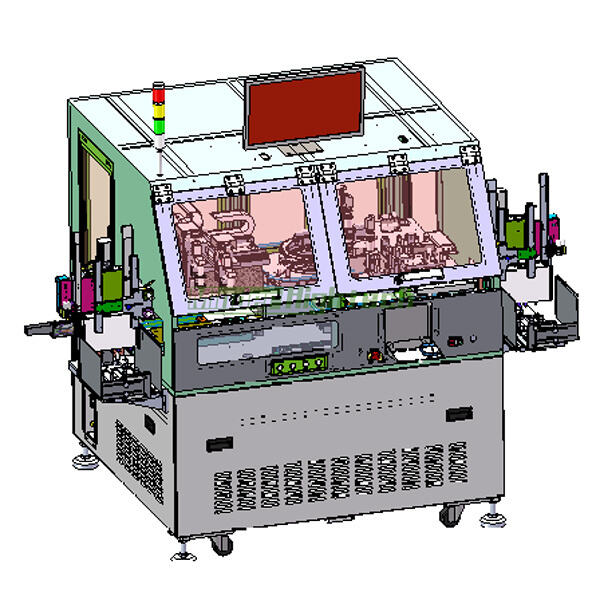

Minder-Hightech has grown into a renowned brand in the world of CMP process. With our decades of experience with machine solutions and our good relationships with overseas customers we developed "Minder-Pack" which focuses on the manufacturing solution for packages as well as other high-end machines.

Minder-Hightech represents the semiconductor and CMP process products business in service and sales. We have more than 16 years of experience in the field of equipment sales. The company is committed to provide customers with Superior, Reliable, and One-Stop Solutions for machinery equipment.

Our CMP process products are Wire bonder Dicing Saw, Plasma surface treatment Photoresist removal machine Rapid Thermal Processing, RIE, PVD, CVD, ICP, EBEAM, Parallel sealing welder, Terminal insertion machine, Caparitar winding machines, Bonding tester, etc.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved