Inductively coupled reactive ion etching technology is a type of RIE. This technology achieves decoupling of plasma ion density and ion energy by independently controlling ion flux, thereby improving the control accuracy and flexibility of the etching process.

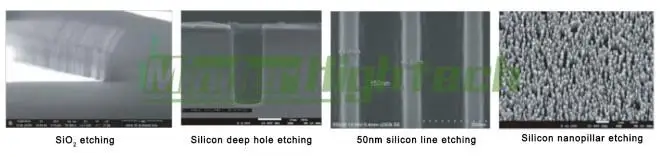

The high-density inductively coupled reactive ion etching (ICP-RIE) series products are based on inductively coupled plasma technology and are aimed at fine etching and compound semiconductor etching needs. It has excellent process stability and process repeatability, and is suitable for applications in silicon semiconductors, optoelectronics, information and communications, power devices, and microwave devices.

Applicable Materials:

1. Silicon-based materials: silicon (Si), silicon dioxide (SiO2), silicon nitride (SiNx), silicon carbide (SiC)...

2. III-V materials: indium phosphide (InP), gallium arsenide (GaAs), gallium nitride (GaN)...

3. II-VI materials: cadmium telluride (CdTe)...

4. Magnetic materials/alloy materials

5. Metal materials: aluminum (Al), gold (Au), tungsten (W), titanium (Ti), tantalum (Ta)...

6. Organic materials: photoresist (PR), organic polymer (PMMA/HDMS), organic thin film...

7. Ferroelectric/photoelectric materials: lithium niobate (LiNbO3)...

8. Dielectric materials: sapphire (Al2O3), quartz...

Related applications:

1. Grating etching: used for 3D display, micro-optical devices, optoelectronics, etc.;

2. Compound semiconductor etching: used for LED, laser, optical communication, etc.;

3. Patterned sapphire substrate (PSS);

4. Lithium niobate (LiNO3) etching: detectors, optoelectronics;

Item |

MD150S-ICP |

MD200S-ICP |

MD150CS-ICP |

MD200CS-ICP |

MD300C-ICP |

||||

Product size |

≤6 inches |

≤8 inches |

≤6 inches |

≤8 inches |

Custom≥12inches |

||||

SRF Power source |

0~1000W/2000W/3000W/5000WAdjustable,automatic matching\,13.56MHz/27MHz |

||||||||

BRF Power source |

0~300W/0~500W/0~1000WAdjustable, automatic matching,2MHz/13.56MHz |

||||||||

Molecular pump |

Non corrosive : 600 /1300 (L/s)/Custom |

Anti-corrosion:600 /1300 (L./s)/Custom |

600/1300(L/s) /Custom |

||||||

Foreline pump |

Mechanical pump / dry pump |

Anti corrosion dry pump |

Mechanical pump / dry pump |

||||||

Pre pumping pump |

Mechanical pump / dry pump |

Mechanical pump / dry pump |

|||||||

Process pressure |

Uncontrolled pressure/0-0.1/1/10Torr controlled pressure |

||||||||

Gas type |

H2/CH4/O2/N2/Ar/SF6/CF4/ CHF3/C4F8/NF3/NH3/C2F6/Custom (Up to 12 channels, no corrosive & toxic gas) |

H2/CH4/O2/N2/Ar/SF6/CF4/CHF3/ C4F8/NF3/NH3/C2F6/Cl2/BCl3/HBr/ Custom(Up to 12 channels) |

|||||||

Gas range |

0~5sccm/50sccm/100sccm/200sccm/300sccm/500sccm/1000sccm/Custom |

||||||||

LoadLock |

Yes/No |

Yes |

|||||||

Sample tem control |

10°C~Roomtem/ -30°C~150°C /Custom |

-30°C~200°C/Custom |

|||||||

Back helium cooling |

Yes/No |

Yes |

|||||||

Process cavity lining |

Yes/No |

Yes |

|||||||

Cavity wall tem control |

No/Room tem-60/120°C |

Room tem~60/120°C |

|||||||

Control System |

Auto/custom |

||||||||

Etching material |

Silicon-base: Si/SiO2/ SiNx/ SiC..... Organic materials:PR/Organic film...... |

Silicon-base: Si/SiO2/SiNx/SiC III-V: InP/GaAs/GaN...... IV-IV: SiC II-VI: CdTe...... Magnetic material / alloy material Metallic materials: Ni/Cr/Al/Cu/Au... Organic materials: PR/Organic film...... Silicon deep etching |

|||||||

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved