In electronics production, the positioning of minute solder balls is important for reliable connections on printed circuit boards. The Minder High tech conventional system of placement of solder balls is cumbersome, time-consuming and fraught with a risk of errors, delay and excessive production costs. But with the innovation of lasers, precise solder ball placement has never been easier or more possible.

Placement of Minder High tech solder balls by laser enables more precise and efficient soldering. With a laser-eye, so to speak, manufacturers can carefully place solder balls on the circuit board such that every connection is as precise as can be. This not only decreases potential errors and mistakes, but results in faster assembly, thereby increasing efficiency and lowering production costs.

There are several advantages in using laser for the solder ball placement. Minder High tech Lasers are an incredibly high providing positioning technology, which are capable of placing solder with micron level of precision. This makes sure that every joint is as perfect as can be producing less likely broken solder. Furthermore, lasers are non-contact instruments and can therefore be utilized to “drop” solder balls in sensitive structures without damaging said structures. Such flexibility makes laser solder ball placement extremely suitable for diverse electronics assembly applications.

One of the primary advantages of laser solder ball placement is that perfect solder joints can be achieved. The connections are strong, reliable and uniform when solder balls are accurately located with a laser. This is fundamental for quality and reliability of electronic equipment, especially for high-tech industries where high performance and long life period are required. Minder High tech Laser solder ball placement enables manufacturers to consistently produce perfect solder joints that result in enhanced product quality and improved customer satisfaction.

QC is important in Minder high tech electronics manufacturing, and this type of laser solder ball placement can improve it. Use of lasers for placing solder balls allows manufacturers to obtain a homogeneous, high quality, and accurately placed connection. This lowers the risk of the formation of faults and flaws in the production stage and thus enhances product quality. Furthermore, the placement process of the laser solder ball enables the solder joint quality of the laser solder joint to be monitored and adjusted in real time, so as to further improve quality control.

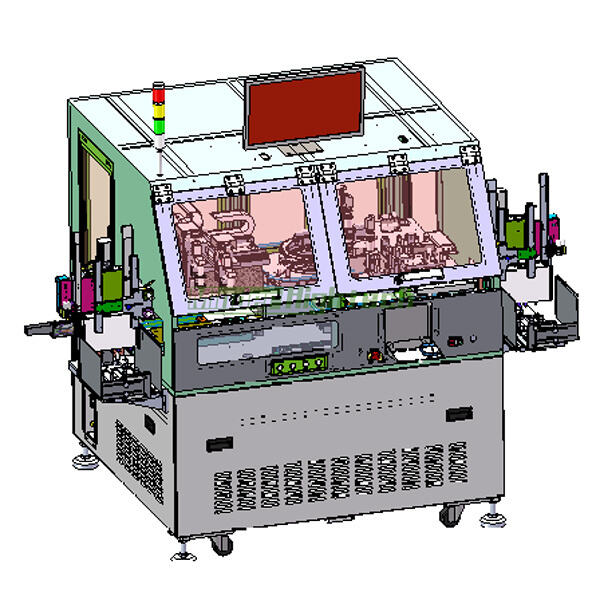

We provide a variety of products. Some examples Laser Solder ball placement: Wire bonder and die bonder.

Minder-Hightech has become a popular brand in the world of industrial. With our many years of Laser Solder ball placement in machine solutions and our long-standing relationships with overseas customers, we created "Minder-Pack" which focuses on the machine solution for packaging as well as other premium machines.

Minder Hightech comprises a team of highly educated engineers, professionals, and staffs with outstanding expertise and experience. Our brand's products have spread to major industrialized countries across the globe aiding customers to improve efficiency, Laser Solder ball placement and increase the quality of their products.

Laser Solder ball placement represents the semiconductor and electronic products sector in service and sales. We have more than 16 years of experience selling equipment. We're committed to providing customers Superior, Reliable and One-Stop Solutions for machinery equipment.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved