Surface grinders are super awesome machines, that make things super smooth and polished. These machines are used in all sorts of industries to get things just right. Get to know more about surface grinding machines and its technical details Dicing saw

When it comes to the world of manufacturing, surface grinding machines have become the magic hand in the business. They use a special tool called a grinding wheel to rub against the surface of a workpiece, so that it is flat or smooth. This is called grinding and it helps to even out-and eliminate any bumps or rough spots on the stone.

One of the coolest things about surface grinding machines is that they are just that – precise. It can make things super flat and smooth, which is pretty important for industries Wafer saw

that depend on precision. The machine’s grinding wheel can also be adjusted to ensure the perfect finish is achieved with every piece, so that everything is ‘just right’.

Surface grinding machines are used across a wide range of industries, including IC packaging automotive, industrial, aerospace, and electronics. They can produce parts for cars, planes and even smartphones! The beauty of those machines is that they can work in so many different kinds of materials: metal and plastic and wood.

Surface Grinding Techniques There are several types of surface grinding, but one thing they all have in common is the wheels. Some are big and muscular; some are smaller, lean and quick. Some machines have a magnetic chuck to hold the material in place, while others use a vise or vacuum. No matter what surface grinding machine you employ, they all do essentially the same work, which is great for smoothing and shaping out small (or large) flat pieces of metal or even some wood.

To ensure your surface grinding machine stays in perfect working condition, it is essential to keep it maintained. Just be sure to regularly clean the machine and keep the grinding wheel sharp. Inspect the machine for any loose parts or damage – and be sure to follow the manufacturer's instructions for working with the machine in a safe matter. You can use the surface grinding machine in the right way only if you take good care of the same.

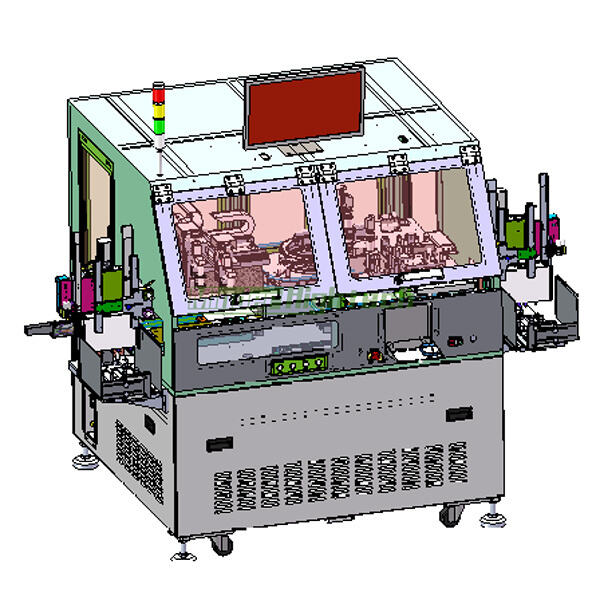

Our primary products are: Surface Grinding Machine, Wire bonder Dicing Saw, Plasma surface treatment Photoresist removal machine Rapid Thermal Processing, RIE, PVD, CVD, ICP, EBEAM, Parallel sealing welder, Terminal insertion machine, Caparitar winding machines, Bonding tester, etc.

Minder Hightech is comprised by a group of highly educated experts, highly skilled engineers and Surface Grinding Machine, with impressive professional skills and expertise. Since its inception, our products have been introduced to many industrialized countries around the world and have helped customers increase efficiency, cut costs and enhance the quality of their products.

Minder-Hightech is a service and sales representative for semiconductor and electronic product industry equipment. Surface Grinding Machine over 16 years of experience in sales and service for equipment. The company is committed to providing customers with Superior, Reliable, and One-Stop Solutions for machinery equipment.

Minder-Hightech has grown into a renowned name in the industrial world. Based on our many years of experience with machine solutions, and our strong relations with our Surface Grinding Machine customers We created "Minder-Pack" which focuses on the machine solution for packages and other high-value machines.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved