Ever wondered how quality products are produced without errors? And it’s thanks to technology such as Automated Optical Inspection (AOI), among other methods. AOI makes it easy for companies like Minder-Hightech to ensure that its products are perfect before they ship to customers.

AOI allows Minder-Hightech way to rapidly catch any errors in its products. This amazing invention uses cameras to zoom in on things at a really close range and find things that the human eye could not even see. It can test a lot of products very quickly and assure the Ultrasonic Inspection System are just right. This is what helps us make absolutely sure that no bad product ever, ever makes it to you.

AOI is hugely important when producing electronic parts where the smallest mistake can lead to huge issues. At Minder-Hightech, AOI systems inspect every single part of electronic optical edger components. Which is to say, everything works fine when you use it. It’s sort of like having a super-smart robot watching to see it all fits together just perfectly.

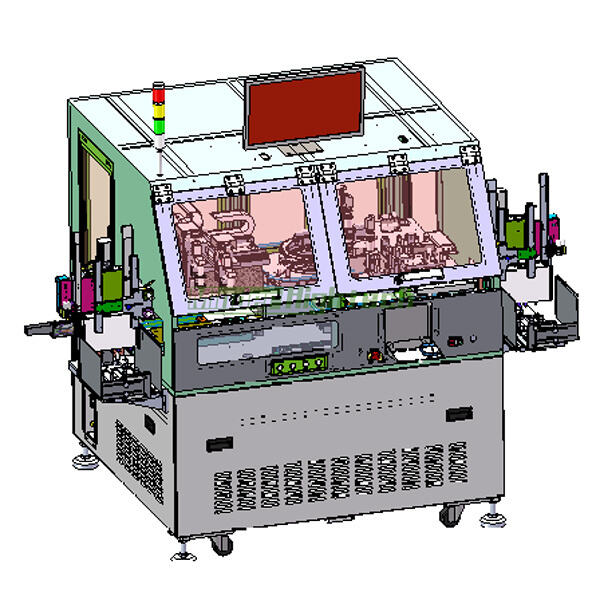

By deploying AOI, Minder-Hightech has made production of products quicker and easier. Previously, workers had to inspect each part by hand, which was time-consuming. Now, thanks to Optical communication Sealing machine, we can do this way more quickly. It means we can produce more in less time with diminishing impact on quality.

When you get a product from Minder-Hightech, you expect the same great things every time. We help close this gap by verifying that everyone does their job in the same way and in the same place. This assures you that no matter when you make your purchase, your product will be defect-free or we’ll replace it for free.

Benefiting from AOI doesn’t just speed things up, it also helps to keep costs in check. This saving is then passed on to you, the customer, in the form of lower prices. And by identifying errors early, Minder-Hightech saves millions of dollars in troubleshooting issues, allowing us to remain cost-competitive.

Minder-Hightech is now a very well-known brand in the industrial market, based upon decades of experience with machine solutions and Automated Optical Inspection with overseas customers from Minder-Hightech, we created "Minder-Pack" which focuses on the manufacturing of packages solution as well as other high-value machines.

Minder Hightech is Automated Optical Inspection by a group of high educated experts, skilled engineers and staff, who have impressive professional skills and expertise. Our brand's products have been introduced to many industrialized countries around the world to help customers increase efficiency, reduce costs, and increase product quality.

Minder-Hightech is a service and sales representative for semiconductor and electronic product industry equipment. We have more than 16 years of experience selling equipment. We are committed to offering customers Superior, Reliable and Automated Optical Inspection for machinery equipment.

Our primary products are: Die bonder, Wire bonder, Wafer grinding Dicing saw Automated Optical Inspection, Photoresist removal machine, Rapid Thermal Processing, RIE, PVD, CVD, ICP, EBEAM, Parallel sealing welder, Terminal insertion machine, Caparitar winding device, Bonding tester, etc.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved