Among the hottest technologies for semiconductor manufacturing today, one innovation reigns as a top computer chip technology: Wafer stealth laser dicing. This new process offers precision cutting, which is necessary to produce tiny complex components for the electronics in today’s smartphones and computers.

Foil Stealth Laser Dicing wafer foil A strong laser beam cuts foils with a high degree of precision. The process includes beaming the laser at the surface of the wafer, comprised of materials such as silicon or gallium arsenide. Because the laser beam creates high temperature, the cuts can be made clean and accurately, in such a way that the parts do not have to be damaged during the production.

One of the significant benefits of the Wafer Stealth Laser Dicing is that it provides an ideal solution to achieve max yield and overall quality in semiconductor manufacturing. Through the use of this mechanism, manufacturers are able to increase their yields and produce better quality components. By achieving precision dicing, Wafer stealth laser dicing creates all components exactly the same size and shape, which ultimately contributes to enhanced performance and reliability of electric products.

Following are some benefits to the use of Wafer Stealth Laser Dicing in semiconductor production: One of the primary advantages is the precision cutting power that such a technology accompanies. Wafer stealth laser gives manufacturers the ability to make components to very exacting tolerance, making certain that each part conforms to the precise requirements to function at its best. Furthermore, this technology facilitates a higher speed of processing with the associated higher manufacturing output and lower cost.

All in all, Wafer Stealth Laser Dicing represents a game-changing solution for the semiconductor industry. With its accurate cutting capabilities, yield and quality improvements and other benefits, this technology is helping to increase the efficiency and effectiveness of semiconductor manufacturing. And with wafer laser dicing, manufacturers can create high-quality components that will enable electronic devices to work like new for longer.

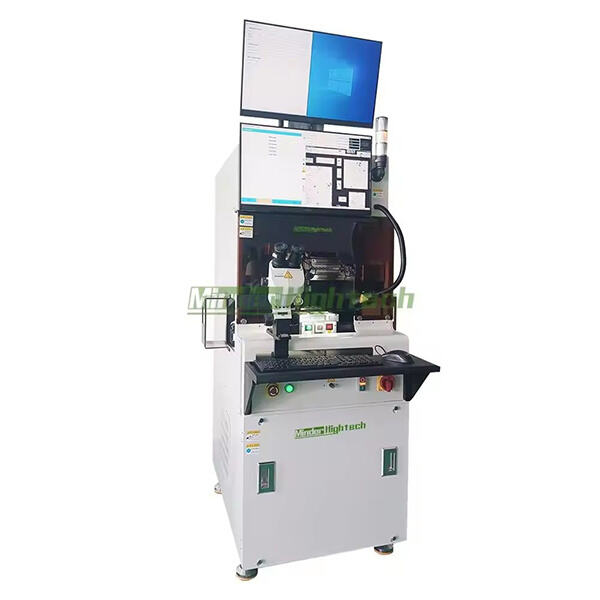

Minder Hightech is comprised by a Wafer Stealth Laser Dicing of high educated specialists, experienced engineers and staffs, with impressive professional skills and expertise. Until today, our brand's products have travelled to major industrialized countries around the world and have helped customers increase efficiency, decrease costs, and increase the quality of their products.

Minder-Hightech is a service and sales representative for semiconductor and electronic product industry equipment. Wafer Stealth Laser Dicing over 16 years of experience in sales and service for equipment. The company is committed to providing customers with Superior, Reliable, and One-Stop Solutions for machinery equipment.

Minder-Hightech is now a very well-known brand in the industrial world, based on decades of experience with machine solutions and good relationship with oversea customers of Minder Hightech, we Wafer Stealth Laser Dicing "Minder-Pack" which focuses on the manufacturing of packages solution, as well as other high value machines.

We offer a range of products. These include Wafer Stealth Laser Dicing.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved