Thinning equipment for the latter wafer is very essential in the manufacture of computer chips. They contribute to making the chips super skinny and super sleek so you can start working.

One of the most critical things that wafer thinning machines now do is ensure that all the chips are the same thickness. That’s important, because if the chips aren’t all the same thickness, they may not perform properly. Minder-Hightech Wafer saw thinning machines employ special tools that shave slivers off the chip until it reaches the desired thickness. This is in order to ensure that all the chips are identical and will all function in the same way.

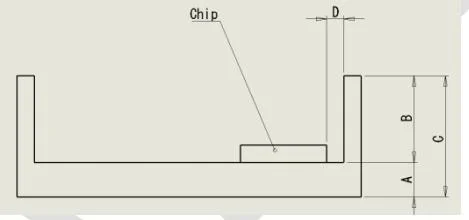

Wafer thinning is a very critical process in semiconductor industry. Once the chips are fabricated, they are placed into the wafer thinning machine. The chips are made very thin with the aid of a special grinding tool in the machine. That is significant because the chips need to be thin so that they can fit in small electronic devices, such as phones and computers. The Minder-Hightech Wafer dicing thinning machine gradually and meticulously takes out the remaining materials on the chips until they reach the correct thickness.

Microelectronics is a very important area of technology relating to the design and manufacture of very small electronic devices. Wafer thinning machines are critical in microelectronics to ensure the chips have the correct size and shape. You cannot build miniaturised electronic devices such as smartphones and tablets without wafer thinning machines. These Minder-Hightech Wafer cutting machines have helped ensure that the chips are thin enough to fit inside these devices so they work properly.

There are many advantages of employing devices for wafer thinning for the manufacture of semiconductors. One of the big advantages is that they allow you to get a really thin, smooth chip. This is significant because if the chips aren’t thin enough, they might not work in tiny electronic gadgets. Another advantage wafer thinning machines and Wafer cleaning solution also provide a way to ensure that all of the chips are of the same thickness. This is critical for making sure all the chips will function as expected.

These machines can cut away minuscule slices of the wafer in just a fraction of a second, which can speed up production. They also even everything out to make sure all of the chips are of the same thickness, which is key for getting that quality crunch! On the whole, wafer thinning machines and wafer plasma debonding are simplifying and making semiconductor manufacturing more dependable.

We offer Wafer thinning machine range of products, including: Wire bonder and die bonder.

Minder-Hightech has grown into a renowned name in the industrial world. Based on our many years of experience with machine solutions, and our strong relations with our Wafer thinning machine customers We created "Minder-Pack" which focuses on the machine solution for packages and other high-value machines.

Minder Hightech is Wafer thinning machine by a group of high educated experts, skilled engineers and staff, who have impressive professional skills and expertise. Our brand's products have been introduced to many industrialized countries around the world to help customers increase efficiency, reduce costs, and increase product quality.

Minder-Hightech is a sales and service representative for electronic and semiconductor products industry equipment. We have over Wafer thinning machine of experience in sales and service for equipment. The company is committed to providing customers with Superior, Reliable, and One-Stop Solutions for machinery equipment.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved