Physical vapor deposition is a cool process scientists and engineers use to coat objects with a thin layer of mater. It’s sort of like painting, only you’re using super tiny particles rather than paint. Read on and know how PVD works and why you need it.

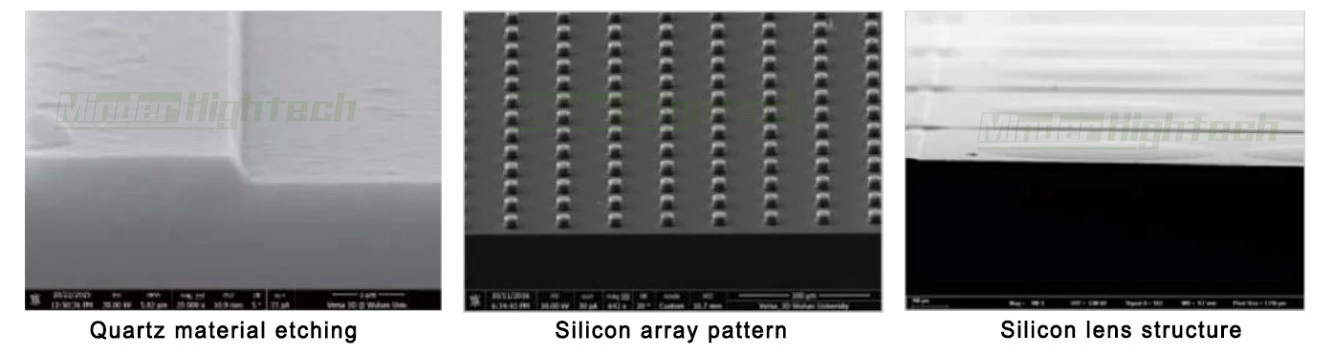

Minder-Hightech Physical vapor deposition and Wire bonder involves heating up solid materials until they become vapor. That vapor then becomes bound to a surface and creates a film. Basically, when water boils and becomes steam, only it’s other substances doing the transforming. This method can be used to make things stronger, more durable or simply to look really cool with shiny coatings.

There are also a number of methods of physical vapor deposition, such as sputtering and evaporation. Sputtering involves high-energy particles knocking atoms out of a target material, and evaporation heats the material until it becomes vapor. These Minder-Hightech Wire bonding machine methods require exacting control of temperature, pressure and other variables to ensure the resulting coating is just right.

Physical vapor deposition is employed in a wide range of industries, from creating computer chips to coating eyeglasses and boosting the performance of power tools and auto parts. Thin layers produced by Minder-Hightech physical vapor deposition and Wire bonding test can help an object last longer, shine more brightly, or conduct electricity better, depending on the materials employed. That makes them valuable in everything from electronics to aerospace.

An added bonus with physical vapor deposition is its ability to produce very thin, uniform coatings, critical for numerous applications. But doing that can be slow and costly, particularly for larger objects. And the Chip Wire Bonder are also restrictions concerning the materials to be deposited and the maximum coating thickness.

Physical vapor deposition is a field in which scientists and engineers are working to constantly improve to facilitate speed and costs while maintaining its film quality. An exciting line of research deals with the formulation of coatings that have special functionalities, like self-healing or antibacterial features, through the application of novel materials and methods. These changes could create additional potential applications for physical vapor deposition and Automated Wire Bonding in a variety of industries.

Minder-Hightech is now a very well-known brand in the industrial market, based upon decades of experience with machine solutions and Physical vapor deposit with overseas customers from Minder-Hightech, we created "Minder-Pack" which focuses on the manufacturing of packages solution as well as other high-value machines.

Minder-Hightech represents the semiconductor as well as electronic products industry in sales and service. Our equipment sales experience spans 16 years. The company is committed to offering customers Physical vapor deposit, Reliable, and One-Stop Solutions for machinery equipment.

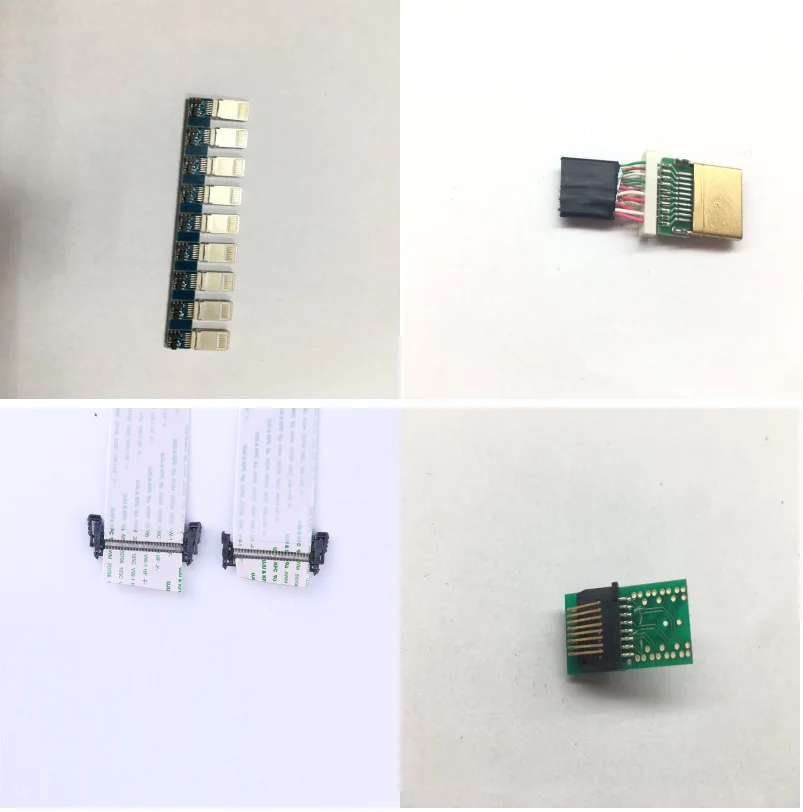

We have a Physical vapor deposit range of products, including: Wire bonder and die bonder.

Minder Hightech is Physical vapor deposit by a group of high educated experts, skilled engineers and staff, who have impressive professional skills and expertise. Our brand's products have been introduced to many industrialized countries around the world to help customers increase efficiency, reduce costs, and increase product quality.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved