ComoRobot, the technology which will make factories deliver their products quicker and better. According to Minder-Hightech, the advanced machines maker company, they have created Robots that can fit glue on an item in a few seconds. This is how with the help of this ability Companies can produce items in a less amount of time and chances of error reduced during manufacturing.

Wire bonder in factories has plenty of good things to say about it. For starters, these robots are able to coat things with glue far more quickly than a person doing it manually. It is fast, allowing factories to produce things very quickly and hence meet customer demand and satisfy orders. Though to be honest, robots are built to be incredibly precise as well. This precision means that they make fewer errors than humans. As a result, they can build much higher-quality products that live up to the expectations of their users.

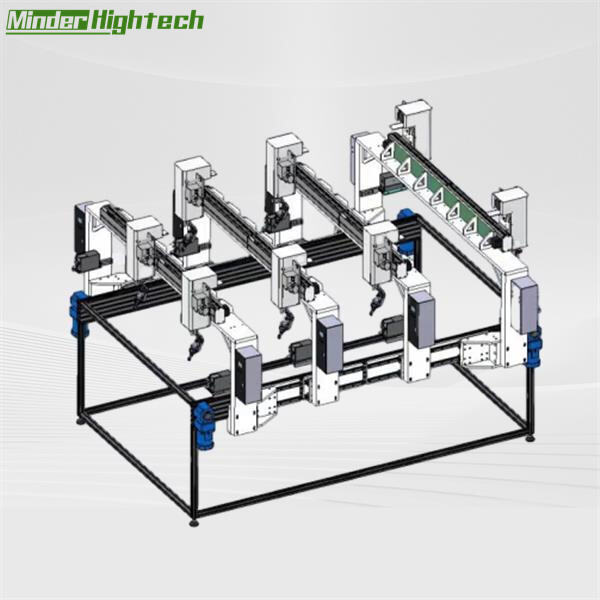

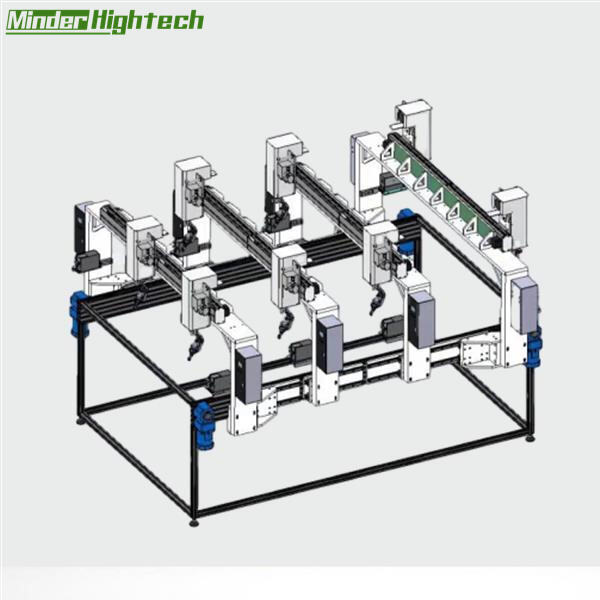

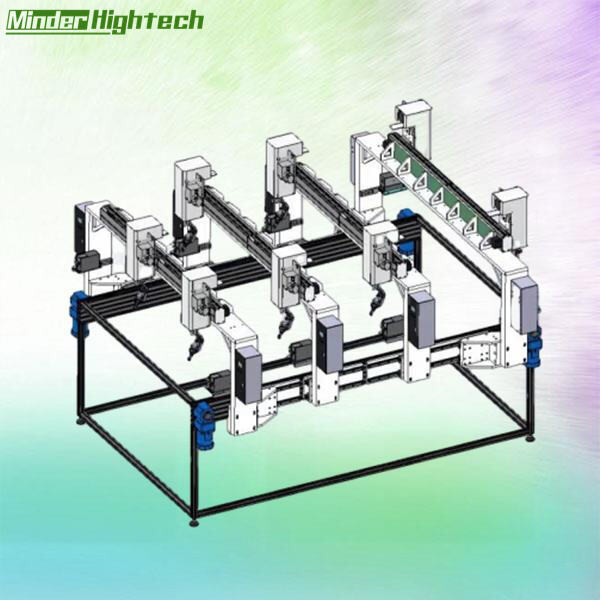

In simple words, Wire bonding machine allows a robot arm to apply glue to things being assembled over an assembly line. A computer is hooked up to the robotic arm, directing the arm on where to go The computer also regulates the amount of glue administered to each piece. By being able to control things carefully so they always come out looking identical and working correctly, companies can keep a decent level of quality. That still makes it worthwhile on our side, because otherwise we need to maintain a very high quality bar in all the things we make.

Robotic Glue Dispensing technology has many compelling advantages It accomplishes this by helping factories in two ways. Because a robot can spend glue much quicker than human workers, this implies that business owners can create a higher volume of goods in less time. In addition, less tape is ultimately wasted when robots make fewer mistakes. This process reduces waste and allows companies to save money on materials and resources. The use of robots can also directly lead to a safer work environment. In addition to increasing precision and accuracy due to human variation from the equation, less injuries will result as well since applying glue over a sustained period is physically draining consequently it can lead to fatigue/bodily harm but since those tasks require humans, the collaborative bond between humans and robots improves safety.

For Many Factories, the Importance of Robotic Glue Dispensing Cannot Be Overstated They will be able to manufacture more items and those items will also have better quality. These better-quality products results in companies making more money and having a greater customer base that likes the product they receive. Another benefit, this time for employees — companies using robots can offer a much safer workspace. Safety remains a key priority, and using near-human robots minimizes risks that exist on the factory floor.

We are a manufacturing company, and like every manufacturing case maximizing our output rate is the key to success. Implemented Robotic Glue Dispensing The most widely used method to get the desired result is by putting in place the Robotic Glue Dispensing technology. This way, companies can make more items and do so in quicker time rather than relying solely on manual labor. Moreover, because robots are invulnerable to problems, there is less error in the products that go to the market. By delivering the highest level of quality, can satisfy customers further and this makes it likely that you will have return buyers down increasing the profits of companies.

Minder-Hightech is a sales and service representative for electronic and semiconductor products industry equipment. We have over Robotic Glue Dispensing of experience in sales and service for equipment. The company is committed to providing customers with Superior, Reliable, and One-Stop Solutions for machinery equipment.

We provide a variety of products. Some examples Robotic Glue Dispensing: Wire bonder and die bonder.

Minder-Hightech has been a sought-after name in the industrial world. With our years of experience in the field of machine solutions as well as our excellent relationships with Robotic Glue Dispensing we developed "Minder-Pack" that focuses on the machine solution for packaging and other valuable machines.

Minder Hightech comprises a team of highly educated engineers, professionals and staff with exceptional expertise and experience. The products we sell are being used in many Robotic Glue Dispensing all over the world, helping our clients improve their efficiency, cut costs and improve their product's quality.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved