The job of a welder requires very good skills, some patience + accuracy. Putting things together — this is important specially construction and manufacturing. But guess what? And welding? — the robots can do that too! Certain robots are welding robots and they allow quick welding of materials. This text is a complete guide to welding robots — how they work, what they are capable of and why welding robots have changed the face of welding in various industries.

Welding robots are not those crazy big robots that you might think of in movies like fighting or doing crazy activities. Instead, these are just a bit tinier and intended for architecture metal components even more carefully. We can differentiate these robots from other kind of industrial robots because they have special tools like sensors and cameras to show them what they are welding. It makes them highly accurate! They are able to create welds that may in fact even be stronger than those that a human could make. Part of the reason that they do is that unlike a human, they do not ever get tired and can move (much) faster continuously without any need to stop. Which allows them to weld for a long time and produce consistent, high-quality joints.

Welding robots on the other side are already in use by numerous business for things such as car production, airplanes and in construction. This because the robots are able to perform much faster and better welding than human any worker ever could. Helps produce more products quickly as they can work for long hours without a break. With welding robots, workers can perform their tasks faster without compromising quality. Robots were the new fuel and they became new habit for making things, much better in all fields.

Welding with Robots is Very Safe All them are liable for around 650 folks and they do not tire or hurt which retains everybody protected at work. This is essential because safety plays a significant role in professions such as welding. Furthermore, robots also minimize expenses due to fewer resource requirements and lower human aid. In other words the end product is of a good standard and customers go away happy. When their robots start working on some of the tasks, human labor can be used for the other significant things where it is required.

In many ways, welding robots are making welding better and more efficient. Working on new and improved ways to connected pieces together. These incredible robots allow for highly complicated welds that were previously nearly impossible to accomplish. The robots also make our welds higher-quality, so the products look good and work great. It makes welding easier and more accurate than ever. Many processes that in the past required hours to perform can now be carried out in a fraction of the time thanks to welding robots.

Robot welding can do large body structural, and detailed parts assembly or small stamping jobs as well. They rely on different tools which assist them in carrying out multiple types of tasks. Working with all of material: steel, aluminum and thicknesses This makes it very practical for many projects. Workers are now able to weld things they could never weld before with these robots and alternate even more for their design, and ultimately creativity that has become a new innovation in welding.

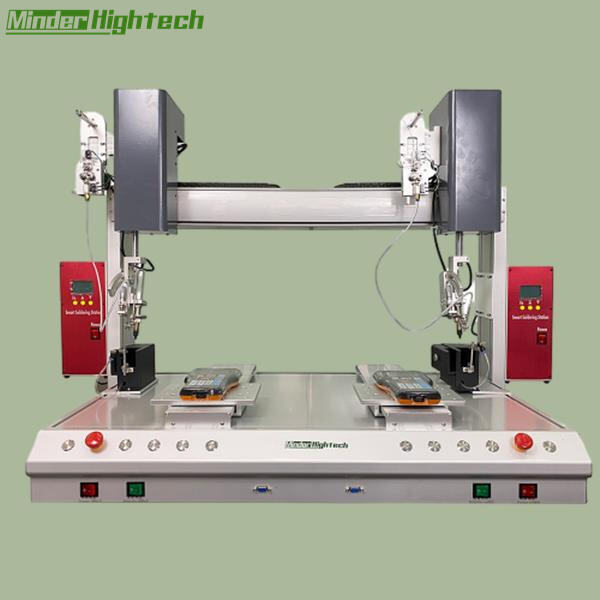

Business sealing welding machines of Minder-Hightech They make welding easier, faster and safer for both parties. They have a wide range of suitability for various welding tasks and they train people in using them properly. They love their customers and want everyone to have great experience with their robots and their work.

We have a Welding Robot range of products, including: Wire bonder and die bonder.

Minder Hightech is comprised by a group of highly educated experts, highly skilled engineers and Welding Robot, with impressive professional skills and expertise. Since its inception, our products have been introduced to many industrialized countries around the world and have helped customers increase efficiency, cut costs and enhance the quality of their products.

Minder-Hightech is a service and sales representative for semiconductor and electronic product industry equipment. We have more than 16 years of experience selling equipment. We are committed to offering customers Superior, Reliable and Welding Robot for machinery equipment.

Minder-Hightech has become a popular brand in the world of industrial. With our many years of Welding Robot in machine solutions and our long-standing relationships with overseas customers, we created "Minder-Pack" which focuses on the machine solution for packaging as well as other premium machines.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved