Important wire bond tests to ensure things are getting connected properly. This completes the test recipes for wire bond. It might be a bit more complicated, there can be some challenges but after all testing, it should result in stability. There are even some great new technologies for wire bond testing.

Knowing the significance of Wire bond tester is similar to ensuring that all the components of a puzzle are perfectly assembled. If one piece wasn't there or was incorrect, the entire puzzle wouldn't be solved. Thus wire bond testing is very important to make the electronic devices work properly. At Minder-Hightech, we understand the significance of proper wire bond tests to ensure a quality product.

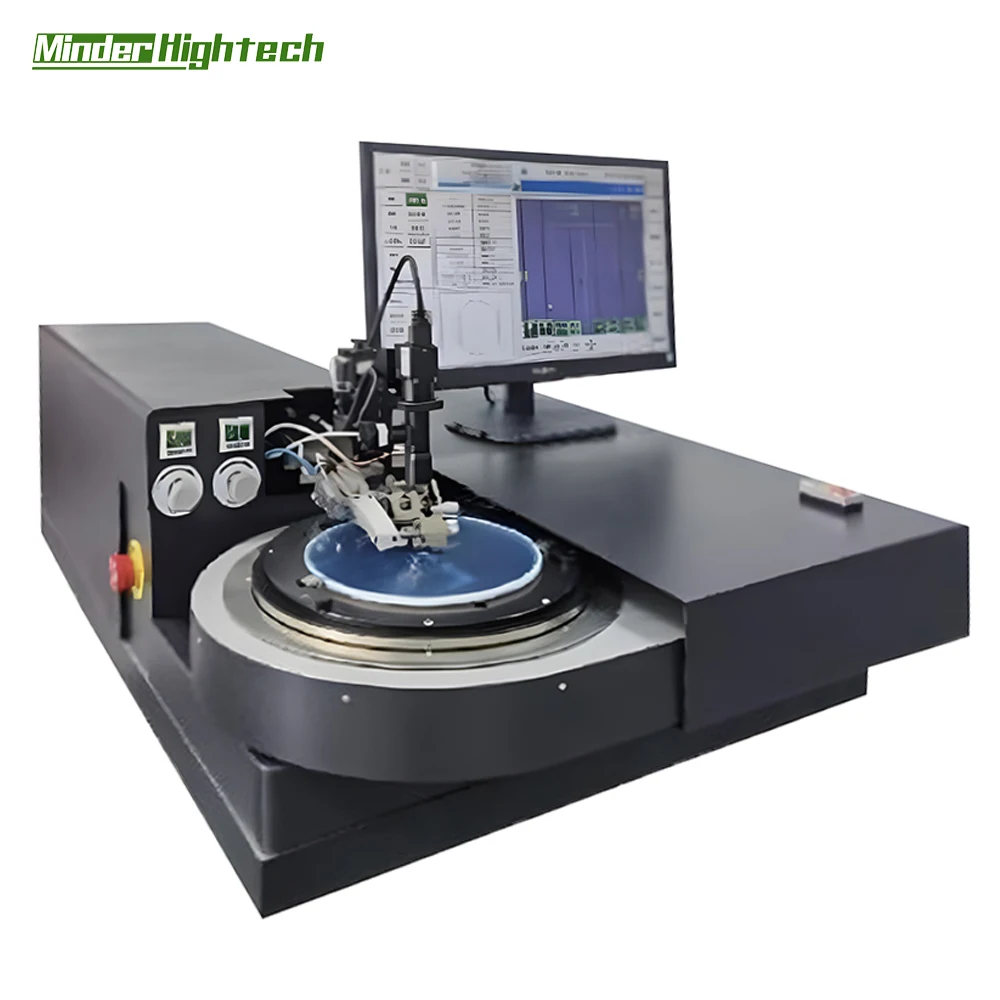

This process involves the connection of fine wires to various locations on a device, and verifying they work properly by applying Minder-Hightech Wire bonder directly to electric circuits. The materials we have to prepare for the test are wires and a special machine. After this, we manually attach the wires to some parts of the device using the machine. Then we perform an electrical test by injecting low current on these wires to see if everything is working as it should. All ready-made should be enough of one and all, or it should work the same completely.

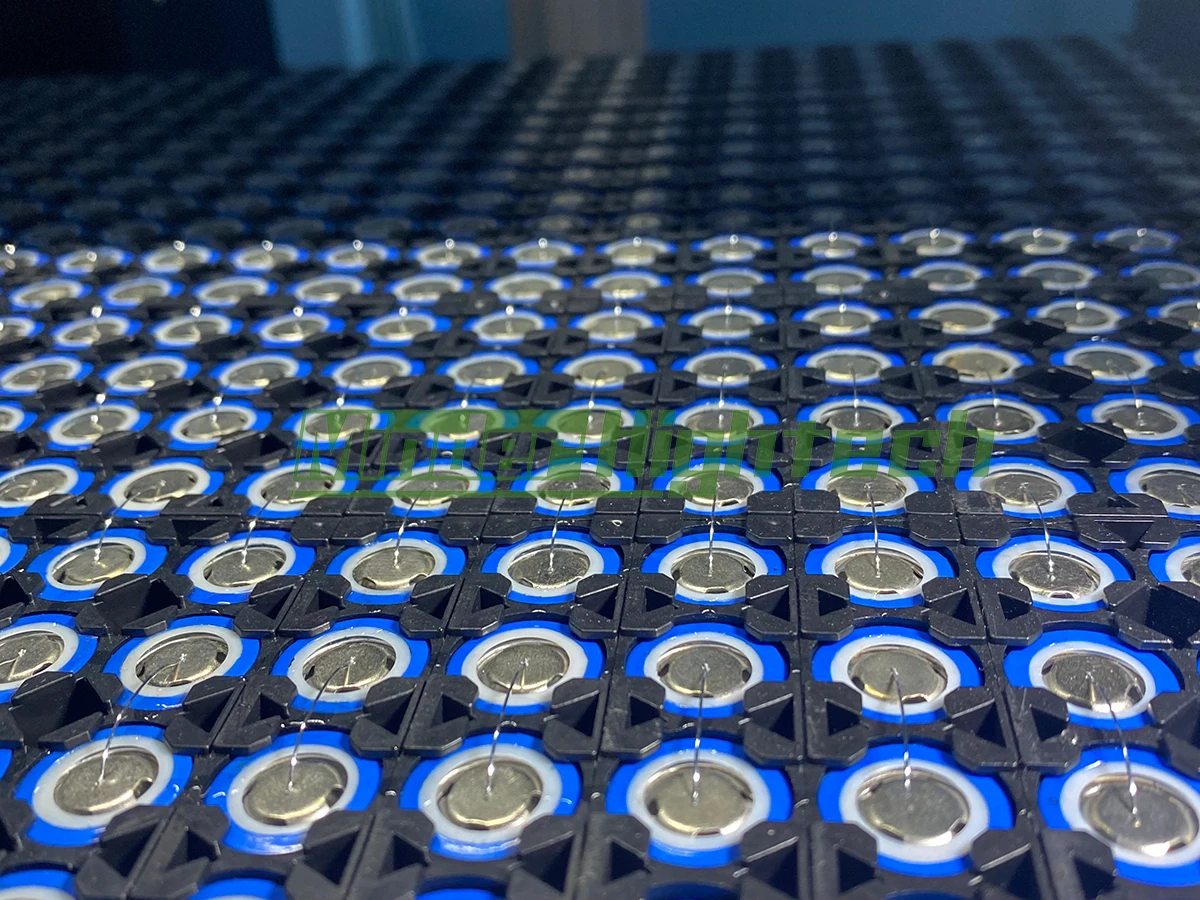

Minder-Hightech Wire Bond testing is not always easy because of some common challenges that it brings. In another topic, they are having fun connecting some wires on the Wire bonding machine but one of the challenges is to link each of them in the correct slot. Connecting the wires in reverse might even just make your device not do anything at all. At the time, one more problem is to generate the wires sturdy adequate for all these Pyromex Parts of electrical energy in order that they could transmit. However, if the wire that is used in manufacturing process is too weak, it can easily break and then there will be a problem with the proper device operation.

Rigorous wire bond testing builds confidence for quality in our products, because we test our product so many times that it will become super reliable wherever you place the WE-IPlus modules. We try to test our products as faithfully as possible for a normal usage of the consumer. Through extensive Chip Wire Bonder testing, you can trust that our products will perform well and be long lasting.

Improved Testing Techniques for Wire Bonding Technology Up to 20 years ago, you had to check the sensors one by one. Now we are able to examine wires at once thanks to new technologies. Nowadays we can also run computer programs that can analyze the test results fast and reliably. Our Automated Wire Bonding are continuously upgraded and updated, while maintaining the integrity of our designs as part of a practice in innovation that serves both us and our customers.

Minder-Hightech has been a sought-after name in the industrial world. With our years of experience in the field of machine solutions as well as our excellent relationships with Wire bond test we developed "Minder-Pack" that focuses on the machine solution for packaging and other valuable machines.

Minder Hightech comprises a team of highly educated Wire bond test, engineers and staff with exceptional expertise and experience. Until today, our brand's products have been marketed to the largest industrialized countries across the globe, helping customers improve efficiency, lower costs and improve product quality.

Minder-Hightech is sales and service Wire bond test of electronic and semiconductor product industry equipment. We have over 16 years of experience in sales and service for equipment. The company is committed to providing customers with Superior, Reliable, and One-Stop Solutions for machinery equipment.

Our primary products are: Die bonder, Wire bonder, Wafer grinding Dicing saw Wire bond test, Photoresist removal machine, Rapid Thermal Processing, RIE, PVD, CVD, ICP, EBEAM, Parallel sealing welder, Terminal insertion machine, Caparitar winding device, Bonding tester, etc.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved