Soldering is the process of joining two metal pieces together by melting and putting a filler metal into the joint. And this technique is used in quite different jobs, particularly in how electronics like computers and phones are made, and how cars are manufactured. A long time ago, soldering needed to be done manually, which took a lot of time and sometimes resulted in messy results or mistakes. But now, with the help of technology, we have robots who can perform this task better and faster!

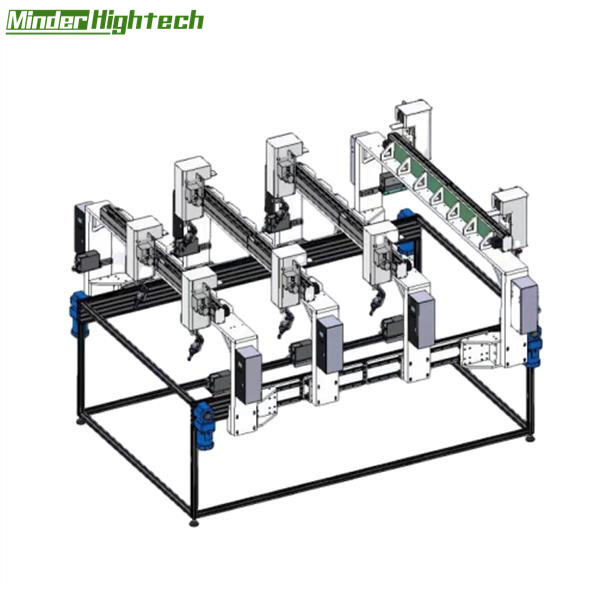

Choosing robots for soldering is sensible, as it makes the processes simpler and better in multiple perspectives. One company in particular, Minder-Hightech, is laboring to develop robotic soldering solutions that eliminate many of the challenges people encountered when soldering by hand. Here are reasons why it is a great idea to use robots.

Safer: Because robots are performing the soldering work, people do not have to be in hazardous portions of the factory. It protects animals, maintains employee safeguards and prevents workplace accidents.

It is revolutionising the way the production of soldering takes place in factories these days. It enables manufacturers to be better and more accurate in their products than ever before. With latest technology, eg Artificial Intelligence (AI) and the Internet of Things (IoT), robots can now collaborate with the other machines within the factory. This cooperative effort ensures everything goes smoothly from beginning to end, streamlining the overall process.

Dawn Of Robots Have Improved The Soldering As A Whole This makes for fewer mistakes, higher quality products, and helps factories save money. When does everyone do things right, customers bring more satisfaction because they get better products. And robots are responsible for keeping workers from harm, too, providing a more relaxed working atmosphere for all parties.

Robotic soldering is not only enhancing manufacturing processes, but also is driving efficiencies and smart factories. Using robots, manufacturers can produce more within a short period of time while keeping quality high and reducing costs. This flexibility means they can respond sharply to shifts in what customers want or need, allowing for easy switching of production lines when needed.

Latest technology with industry-leading automation and robotics is used to guarantee that the soldering process is fool-proof and done perfectly every time. They help by monitoring things like temperature and humidity — key components of successful soldering. These robots watch over meticulously maintained conditions to ensure everything goes according to plan. They also offer real-time information on how the soldering is progressing, allowing workers to adapt and adjust as needed and optimize the process in real time.

Minder-Hightech is sales and service representative of electronic and semiconductor products industry equipment. Our experience with sales of equipment stretches over 16 years. We're committed to providing customers Superior, Robotic Soldering Automatic and One-Stop Solutions in the field of machine tools.

Minder Hightech comprises a team of highly educated engineers, professionals and staff with exceptional expertise and experience. The products we sell are being used in many Robotic Soldering Automatic all over the world, helping our clients improve their efficiency, cut costs and improve their product's quality.

Minder-Hightech has been a sought-after name in the industrial world. With our years of experience in the field of machine solutions as well as our excellent relationships with Robotic Soldering Automatic we developed "Minder-Pack" that focuses on the machine solution for packaging and other valuable machines.

We offer a range of products. These include Robotic Soldering Automatic.

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved