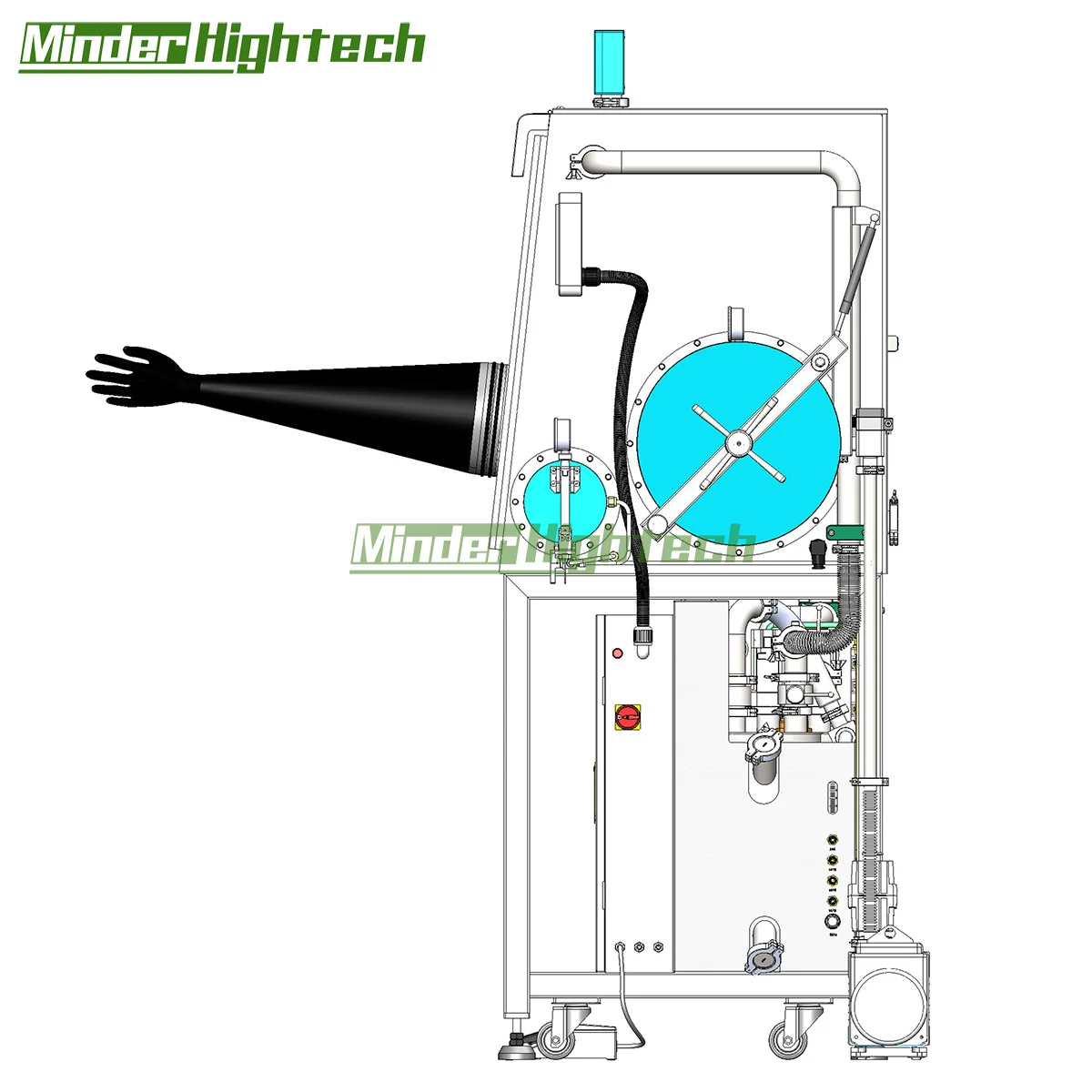

The working gas in the glovebox is between the chamber and the purification column (H2O and O2 adsorber), and it is closed

circulated through pipes, circulation blowers, etc. under the control and monitoring of PLC. When the working gas circulates

through the purification column, its moisture and oxygen are adsorbed and then returned to the chamber. As the cycle time passes,

the H2O and O2 content of the working gas in the chamber will gradually decrease and eventually reach the index of less than 1

ppm. The purification column will saturate after a certain period of cycle, and can be regenerated and reused.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

IS

IS

HY

HY

AZ

AZ

KA

KA