Model |

MDHS-URW2030 |

Operating Air Pressure |

0.4-0.9MPa |

Linear Speed |

5-15m/min |

Output Power |

Approximately 2000W |

Motion Control |

Pneumatic |

Operating Frequency |

20kHz |

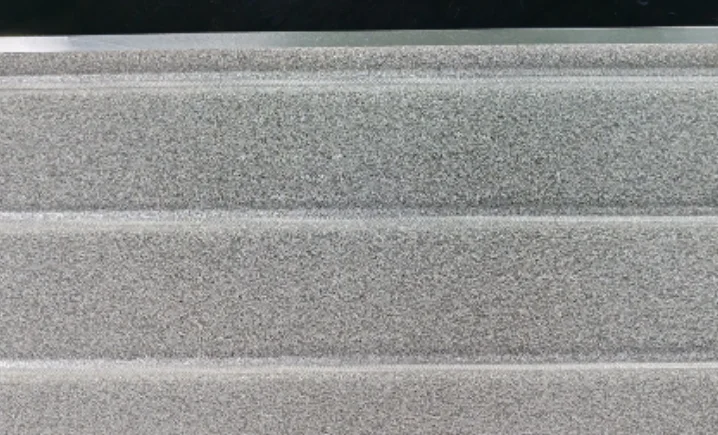

Construction Material |

Square, with square steel connections |

Operating Mode |

Continuous |

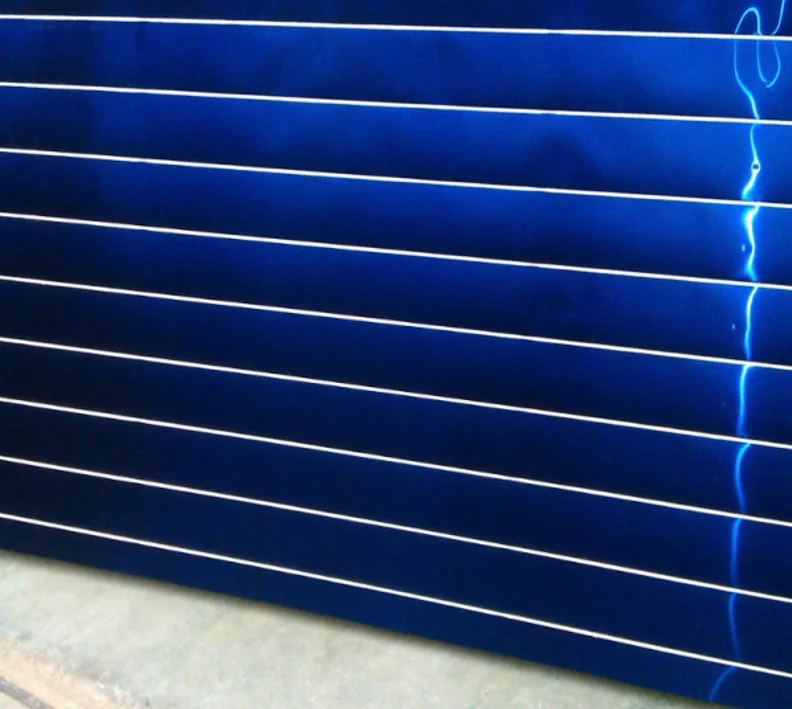

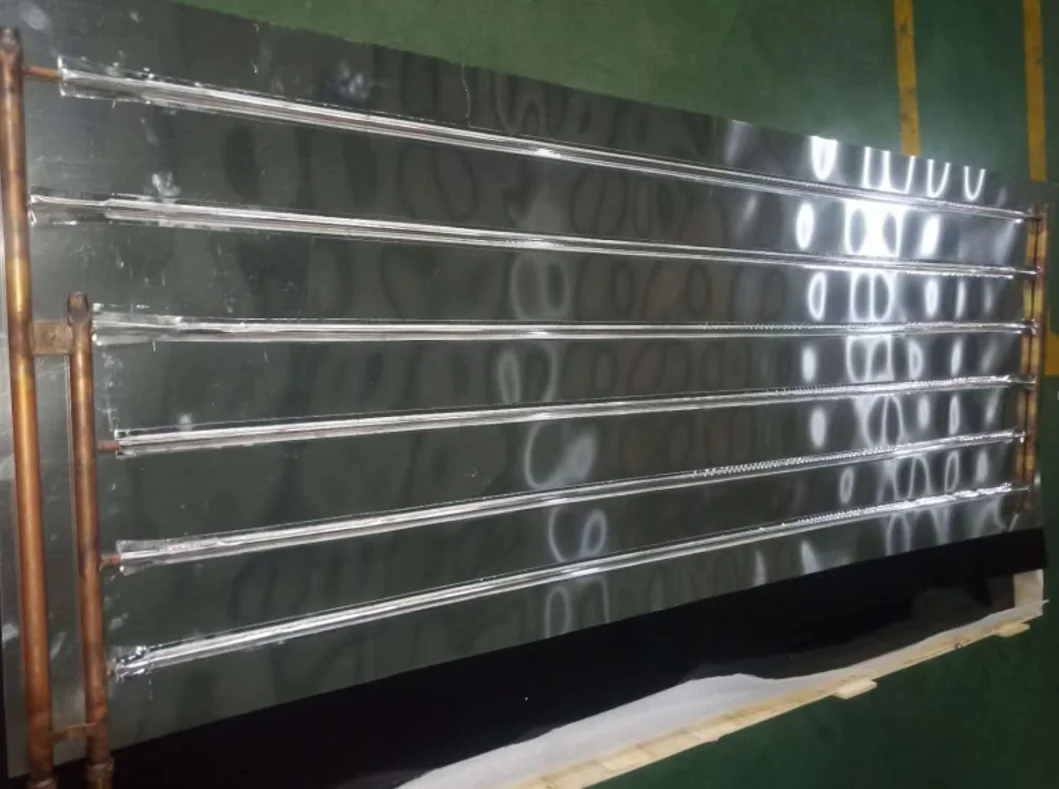

Welding Products |

Welding copper pipes to aluminum plates. |

Maximum welding length |

1.2m |

Copper pipe wall thickness |

0.3mm |

Power Supply |

C380V, 20A, three-phase, five-wire |

Electrical Box Dimensions |

500*400*180mm |

External Dimensions |

Length, Width, and Height (Subject to final design) |

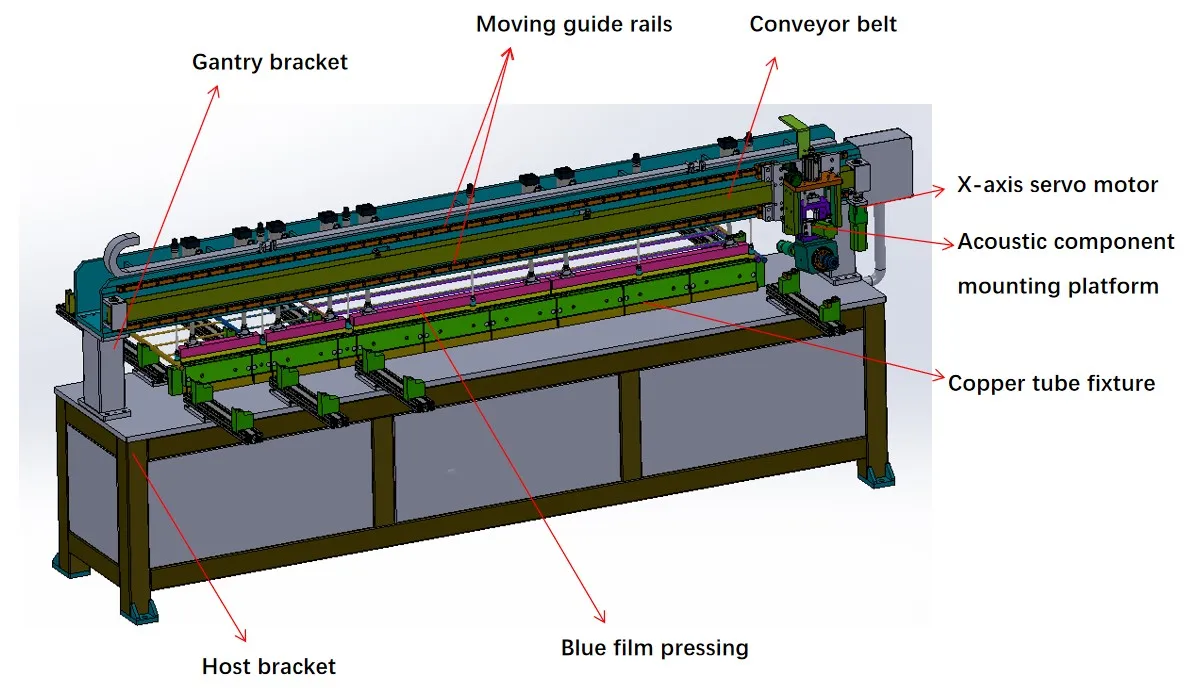

Component Name |

Part Name |

Equipment Drive System |

PLC |

Pneumatic Cylinder |

|

Mechanical System |

Frame |

Support components |

|

Moving components |

|

Workbench |

|

Rollers |

|

Collector plate mobile platform |

|

Collector plate bracket |

|

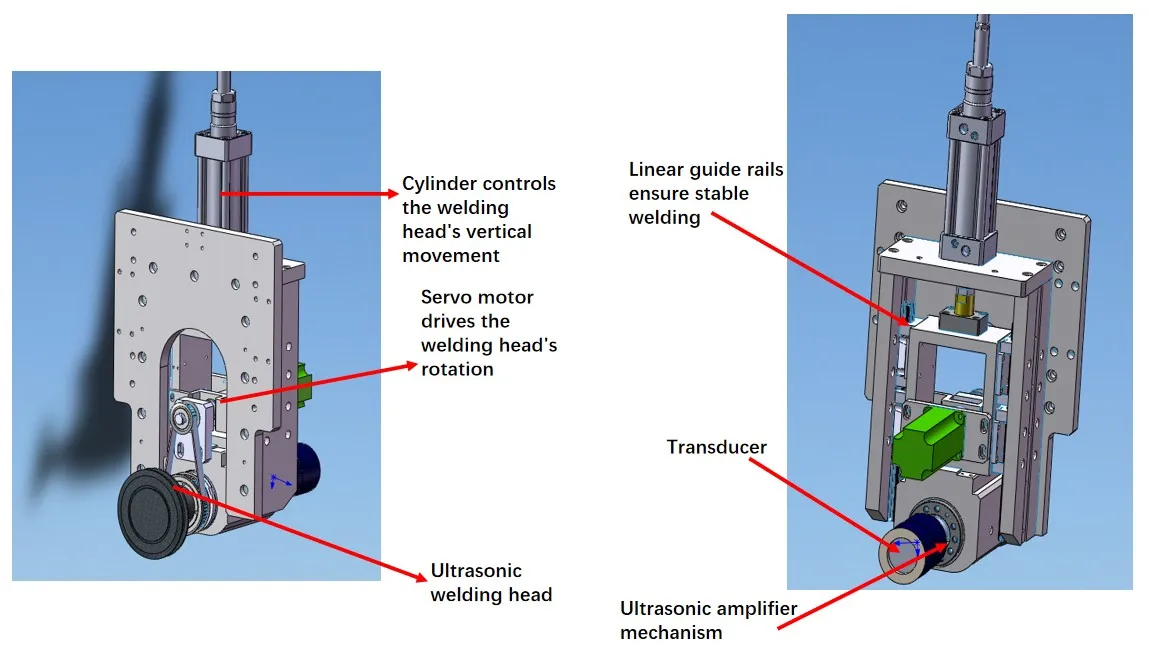

Transmission |

Servo motor |

Cylinder |

|

Linear guide |

|

Pneumatic control components |

|

Electronic Control |

PLC |

Touch Screen |

|

Electronic Control Components |

|

Ultrasonic System |

Ultrasonic Control System |

Ultrasonic Welding Head + Base Die |

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved