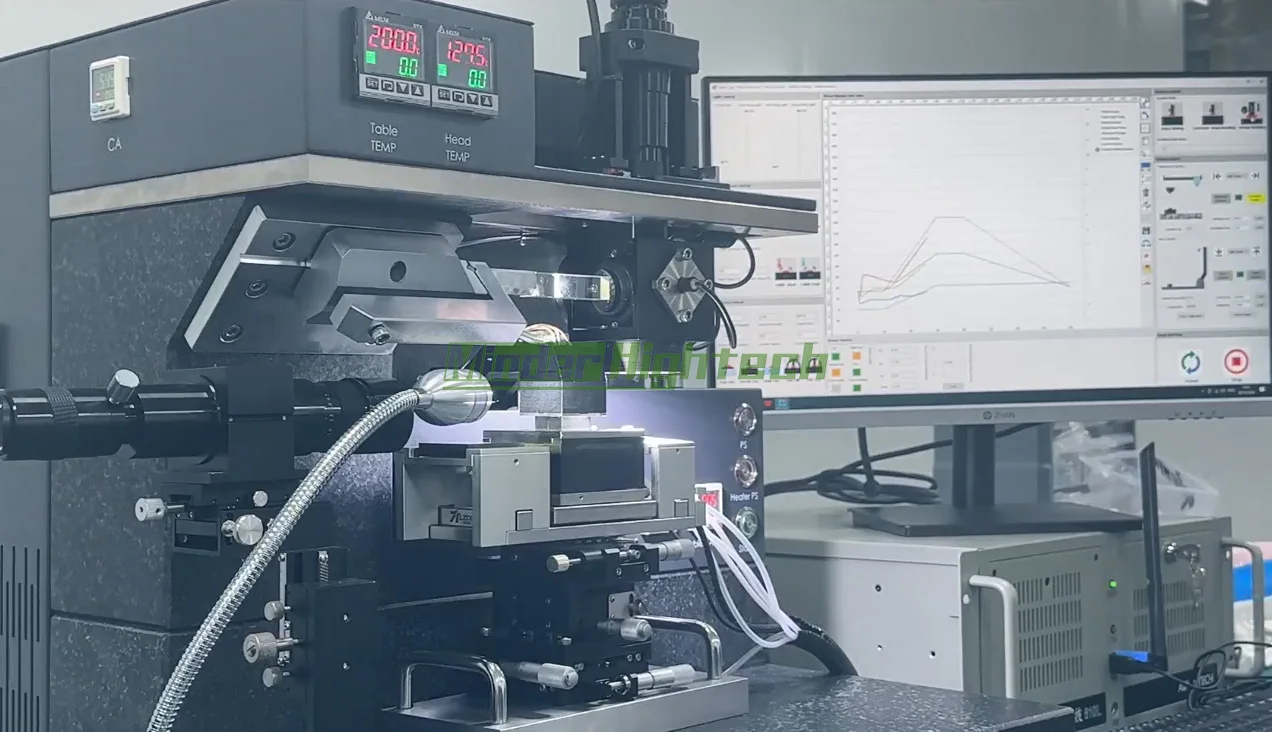

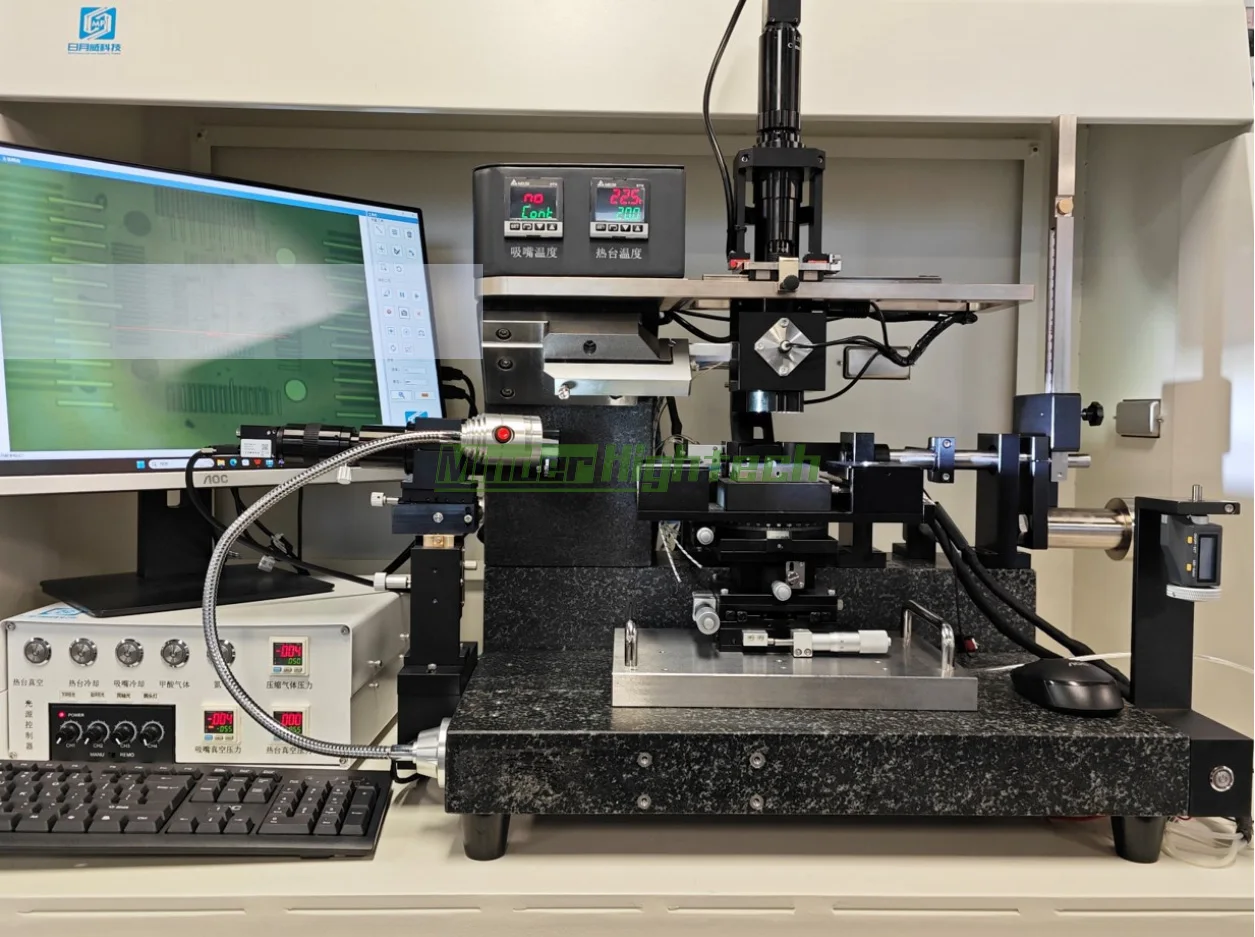

Model |

RYW-ETB05B |

RYW-ETB20 |

RYW-ETB05S |

RYW-ETB05 |

|||

Alignment Accuracy |

±0.5μm |

±2μm |

±0.5μm |

±2μm |

|||

Field of View |

0.5×0.3-5.4×4mm² |

1.2×0.9-14.4×10.8mm² |

0.5×0.3-5.4×4mm² |

1.2×0.9-14.4×10.8mm² |

|||

Substrate Size |

150mm/6-inch(300mm/12-inch) |

||||||

Chip Size |

0.1~40mm |

||||||

Axis Fine Adjustment |

±10° |

||||||

Fine Adjustment Range |

2.5×2.5×10mm Res(0.5μm) |

||||||

Pressure Range |

0.2~30N(Option 100N) |

||||||

Heating Temperature |

350±1℃ (Option 450℃) |

||||||

Heating and Cooling Rates |

Heat: 1~100℃/s; Cool: >5℃/s |

||||||

Operating Range |

100mm×200mm |

||||||

Device Dimensions |

L0.7×W0.6×H0.5m |

||||||

Operation Type |

Semi-Automatic Rotary |

Manual Rotary |

|||||

Device Weight |

120Kg |

100Kg |

|||||

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved