Bonding Area |

200mm*250mm (Adjustable worktable) 200mm*150mm (In-line track, non-standard customized); Z-axis travel: 50mm, θ-axis travel: ±90° |

Bonding Tool Length |

16/19 mm |

Bonding Pressure |

5~300g Low Impact (Absolute accuracy ±1g @ "10g~100g" or 1% @ 100g~300g, repeatability ±0.5g) |

Main Camera Field of View |

4.2mm*3.5mm or 8.4mm*7.0mm |

Interface Standard |

SECS/GEM communication protocol, SMEMA connection standard |

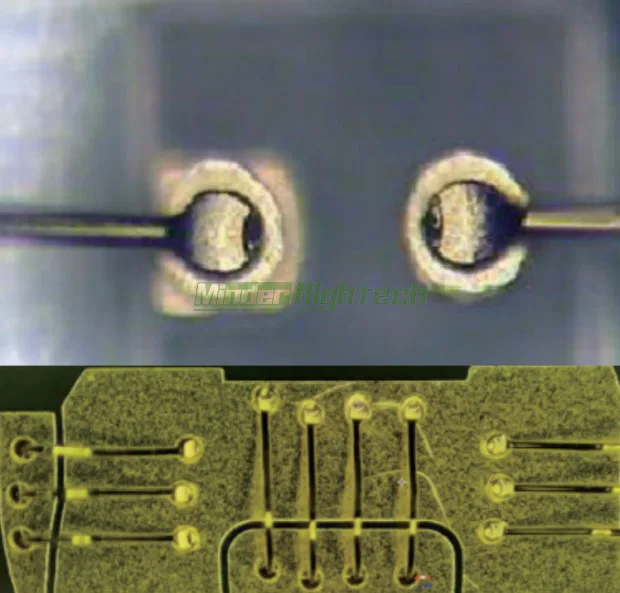

Overall Process Positioning Accuracy |

±3um@3σ (±2um@3σ single item evaluation) |

Cavity Depth (Whole Area) |

10 mm |

Ultrasonic |

4W/100KHz (High precision) |

Auxiliary Camera Field of View (including E_BOX function) |

4.2mm*3.5mm or 8.4mm*7.0mm |

Equipment Dimensions |

1110mm*1350mm*1900mm (Width*Depth*Height) (Adjustable worktable) 1400mm*1350mm*1900mm (Width*Depth*Height) (In-line track) |

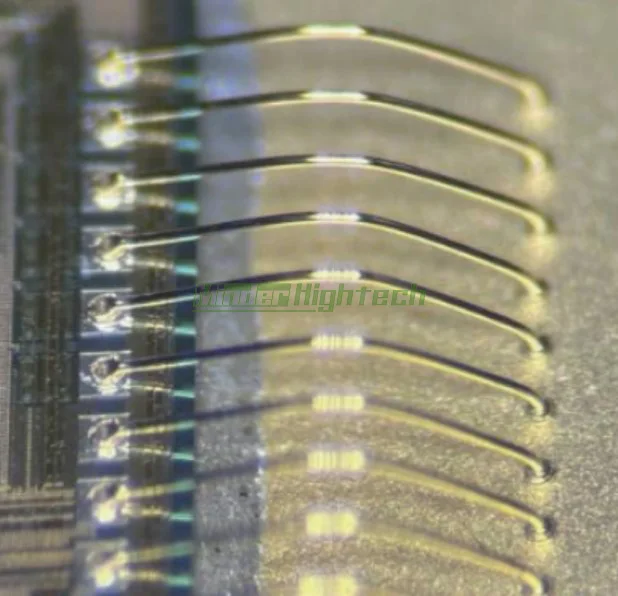

Gold Wire Diameter |

12-50 μm (Silver wire, copper wire non-standard customized, wire diameter range single item evaluation) |

Electronic Ignition |

Multiple Profile real-time control (maximum adaptation to gold wire diameter 75um) |

UPH |

1~4 Wire/S, wire diameter & process & wire arc related |

Material System |

Standard adjustable worktable, customizable in-line track |

Power Supply |

AC 220V ±10% - 10A @ 50Hz |

Weight |

1000 kg |

Compressed Air |

≥10LPM @ 0.5MPa, purified air source |

Vacuum Source |

≥50LPM @ -85kPa |

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved