Bonding Stroke |

15mm*15mm*18mm |

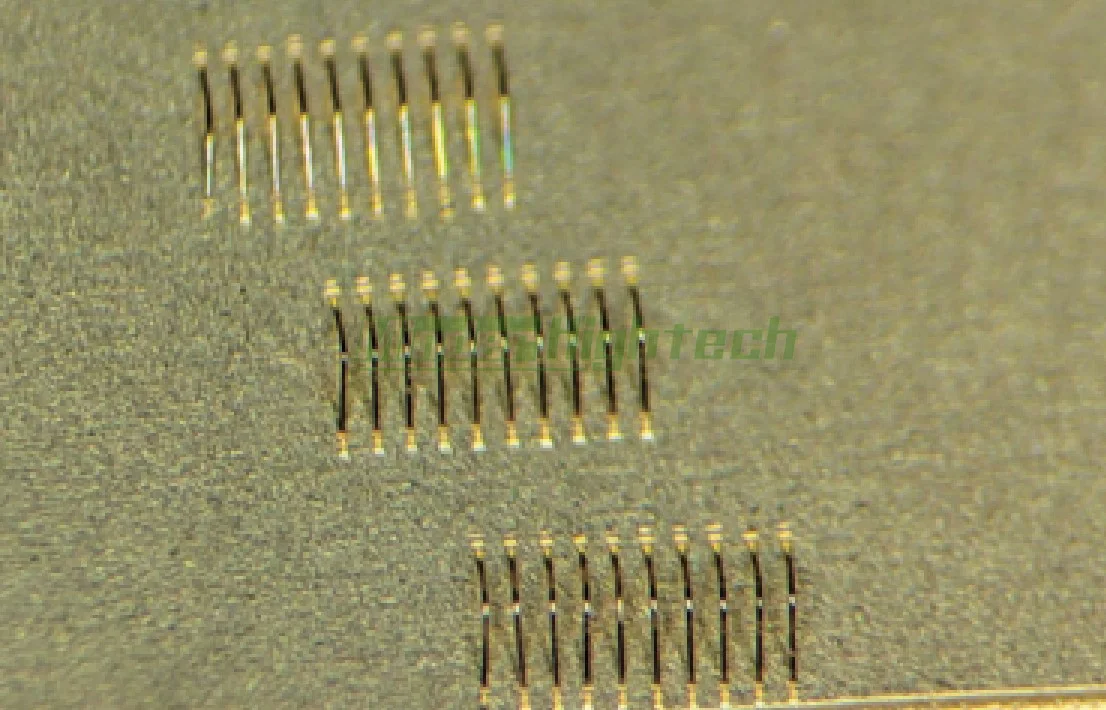

Wire Diameter (Gold/Aluminum Wire) |

18-100μm (Copper wire, ultra-fine wire diameter range requires separate evaluation) |

Spool Size |

1/2 inch, 2 inches |

Bonding Tool Length |

25mm (19mm optional with custom Wire Clamp) |

Cavity Depth (Whole Area) |

15mm (10mm, with 19mm bonding tool) |

Bonding Pressure |

5~150g Low Impact (Absolute accuracy ±1g @ “10g~100g” or 1% @ 100g~150g, repeatability ±0.5g) |

Ultrasonic |

4W/100KHz (High precision) |

Handle Gear Ratio |

8:1 (Standard value) |

Operating Menu |

8″ TFT Touch Screen |

Lifting Platform Size |

250mm*250mm*18mm |

Device Size |

200mm*200mm and above |

Equipment Dimensions |

750mm*580mm*500mm |

Power Supply |

AC 220V±10%-5A@50Hz |

Compressed Air |

|

Weight |

70kg |

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved