|

project

|

Specifications

|

remarks

|

||

|

1 |

Equipment Overview |

Equipment name: Fully auto uniform glue developing machine

|

||

|

Equipment model: MD-2C2D6

|

||||

|

Processing wafer specifications: compatible with 4/6-inch standard wafers

|

||||

|

Process flow of uniform glue: Flower basket slicing → centering → uniform glue (dripping → uniform glue → edge removal, back

washing) → hot plate → cold plate → basket placing Development process flow: Flower basket slicing → centering → development (development solution → deionized water, back washing → nitrogen drying) → hot plate → cold plate → basket placing |

||||

|

Overall size (approximately): 2100mm (W) * 1800mm (D) * 2100mm (H)

|

||||

|

Chemical cabinet size (approximately): 1700(W) * 800(D) * 1600mm (H)

|

||||

|

Total weight (approximately):1000kg

|

||||

|

Workbench height: 1020 ± 50mm

|

||||

|

2 |

Cassette unit

|

Quantity: 2

|

||

|

Compatible size: 4/6 inches

|

||||

|

Cassette detection: microswitch detection

|

||||

|

Slide out detection: Yes, reflective sensor

|

||||

|

3 |

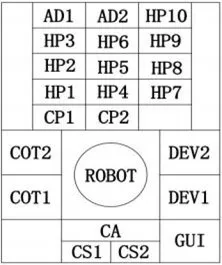

robot |

Quantity: 1

|

||

|

Type: Double arm vacuum adsorption robot

|

||||

|

Degree of freedom: 4-axis (R1, R2, Z, T)

|

||||

|

Finger material: ceramic

|

||||

|

Substrate fixation method: vacuum adsorption method

|

||||

|

Mapping function: Yes

|

||||

|

Positioning accuracy: ± 0.1mm

|

||||

|

4 |

Centering unit

|

Quantity: 1 set

|

Optional optical alignment

|

|

|

Alignment method: mechanical alignment

|

||||

|

Centering accuracy: ± 0.2mm

|

||||

|

5 |

Uniform glue unit |

Quantity: 2 sets (the following are configurations for each unit)

|

||

|

Spindle rotation speed: -5000rpm~5000rpm

|

carrying idler

|

|||

|

Spindle rotation accuracy: ± 1rpm (50rpm~5000rpm)

|

||||

|

Minimum adjustment of spindle rotation speed: 1rpm

|

||||

|

Maximum acceleration of spindle rotation: 20000rpm/s

|

carrying idler

|

|||

|

Dripping arm: 1 set

|

||||

|

Photoresist tube route: 2 routes

|

||||

|

Photoresist nozzle diameter: 2.5mm

|

||||

|

Photoresist insulation: 23 ± 0.5 ℃

|

optional

|

|||

|

Moisturizing nozzle: Yes

|

||||

|

RRC: Yes

|

||||

|

Buffer: Yes, 200ml

|

||||

|

Glue dropping method: center dropping and scanning dropping are optional

|

||||

|

Edge removal arm: 1 set

|

||||

|

Edge removal nozzle diameter: 0.2mm

|

||||

|

Edge removal liquid flow monitoring: float flowmeter

|

||||

|

Flow range of edge removal liquid: 5-50ml/min

|

||||

|

Backwash pipeline: 2 ways (4/6 inch each with 1 channel)

|

||||

|

Backwash flow monitoring: float flowmeter

|

||||

|

Backwash fluid flow range: 20-200ml/min

|

||||

|

Chip fixation method: small area vacuum adsorption Chuck

|

||||

|

Vacuum pressure alarm: digital vacuum pressure sensor

|

||||

|

Chuck Material: PPS

|

||||

|

Cup material: PP

|

||||

|

Cup exhaust monitoring: digital pressure sensor

|

||||

|

6 |

Developing unit |

Shutter:yes

|

||

|

Quantity: 2 sets (the following are configurations for each unit)

|

||||

|

Spindle rotation speed: -5000rpm~5000rpm

|

carrying idler

|

|||

|

Spindle rotation accuracy: ± 1rpm (50rpm~5000rpm)

|

||||

|

Minimum adjustment of spindle rotation speed: 1rpm

|

||||

|

Maximum acceleration of spindle rotation: 20000rpm/s

|

carrying idler

|

|||

|

Developing arm: 1 set

|

||||

|

Developing pipeline: 2-way (fan-shaped/columnar nozzle)

|

||||

|

Developer filtration: 0.2um

|

||||

|

Developer temperature control: 23 ± 0.5 ℃

|

optional

|

|||

|

Developing solution flow range: 100~1000ml/min

|

||||

|

Motion mode of the developing arm: fixed point or scanning

|

||||

|

Fusing arm: 1 set

|

||||

|

Deionized water pipeline: 1 circuit

|

||||

|

Deionized water nozzle diameter: 4mm (inner diameter)

|

||||

|

Deionized water flow range: 100~1000ml/min

|

||||

|

Nitrogen drying pipeline: 1 circuit

|

||||

|

Nitrogen nozzle diameter: 4mm (inner diameter)

|

||||

|

Nitrogen flow range: 5-50L/min

|

||||

|

Developer, deionized water, nitrogen flow monitoring: float flowmeter

|

||||

|

Backwash pipeline: 2 ways (4/6 inch each with 1 channel)

|

||||

|

Backwash flow monitoring: float flowmeter

|

||||

|

Backwash fluid flow range: 20-200ml/min

|

||||

|

Chip fixation method: small area vacuum adsorption Chuck

|

||||

|

Vacuum pressure alarm: digital vacuum pressure sensor

|

||||

|

Chuck Material: PPS

|

||||

|

Chuck Material: PPS

|

||||

|

Cup material: PP

|

||||

|

Cup exhaust monitoring: digital pressure sensor

|

||||

|

7 |

Tackifying unit |

Quantity: 2

|

optional

|

|

|

Temperature range: room temperature~180 ℃

|

||||

|

Temperature uniformity: Room temperature~120 ℃± 0.75 ℃

120.1℃~ 180℃ ± 1.5℃ (Remove 10mm from the edge, except for the ejector pin hole) |

||||

|

Minimum adjustment amount: 0.1 ° C

|

||||

|

Temperature control method: PID adjustment

|

||||

|

PIN height range: 0-20mm

|

||||

|

PIN material: body SUS304, PIN pin cap PI

|

||||

|

Baking gap: 0.2mm

|

||||

|

Overtemperature alarm: positive and negative deviation alarm

|

||||

|

Supply method: Bubbling, 10 ± 2ml/min

|

||||

|

Chamber operation vacuum: -5-20KPa

|

||||

|

8 |

Hot plate unit |

Quantity: 10

|

||

|

Temperature range: room temperature~250 ℃

|

||||

|

Temperature uniformity: Room temperature~120 ℃± 0.75 ℃

120.1℃~ 180℃ ± 1.5℃ 180.1℃~250℃ ±2.0℃ (Remove 10mm from the edge, except for the ejector pin hole) |

||||

|

Minimum adjustment amount: 0.1 ℃

|

||||

|

Temperature control method: PID adjustment

|

||||

|

PIN height range: 0-20mm

|

||||

|

PIN material: body SUS304, PIN pin cap PI

|

||||

|

Baking gap: 0.2mm

|

||||

|

Overtemperature alarm: positive and negative deviation alarm

|

||||

|

9 |

Cold plate unit

|

Quantity: 2

|

||

|

Temperature range: 15-25 ℃

|

||||

|

Cooling method: constant temperature circulating pump cooling

|

||||

|

10 |

Chemical Supply |

Photoresist storage: pneumatic glue pump * 4 sets (Optional tank or electric glue pump)

|

||

|

Glue dispensing volume: maximum 12ml per session, accuracy ± 0.2ml

|

||||

|

Edge removal/back washing/RRC supply: 18L pressure tank * 2 (automatic replenishment)

|

||||

|

Edge removal/back washing/RRC liquid level monitoring: photoelectric sensor

|

||||

|

Photoresist liquid level monitoring: photoelectric sensor

|

||||

|

Discharge of uniform adhesive waste liquid: 10L waste liquid tank

|

||||

|

Developer supply: 18L pressure tank * 4 (Stored in the chemical cabinet outside the machine)

|

||||

|

Deionized water supply: factory direct supply

|

||||

|

Developing liquid level monitoring: photoelectric sensor

|

||||

|

Developer waste discharge: factory waste discharge

|

||||

|

Supply of tackifier: 10L pressure tank * 1, 2L pressure tank * 1

|

||||

|

Level monitoring of tackifier: photoelectric sensor

|

||||

|

11 |

control system |

Control method: PLC

|

||

|

Human machine operation interface: 17 inch touch screen

|

||||

|

Uninterruptible Power Supply (UPS): Yes

|

||||

|

Set encryption permissions for device operators, technicians, administrators

|

||||

|

Signal tower type: red, yellow, green 3 colors

|

||||

|

12 |

System reliability indicators

|

Uptime: ≥95%

|

||

|

MTBF: ≥ 500h

|

||||

|

MTTR: ≤ 4h

|

||||

|

MTBA: ≥24h

|

||||

|

Fragmentation rate: ≤ 1/10000

|

||||

|

13 |

Other functions

|

Yellow light: 4 sets (position: above the glue mixing and development unit)

|

||

|

THC: Yes, 22.5 ℃± 0.5 ℃, 45% ± 2%

|

optional

|

|||

|

FFU: Class 100, 5 sets (process unit and ROBOT area)

|

||||

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved