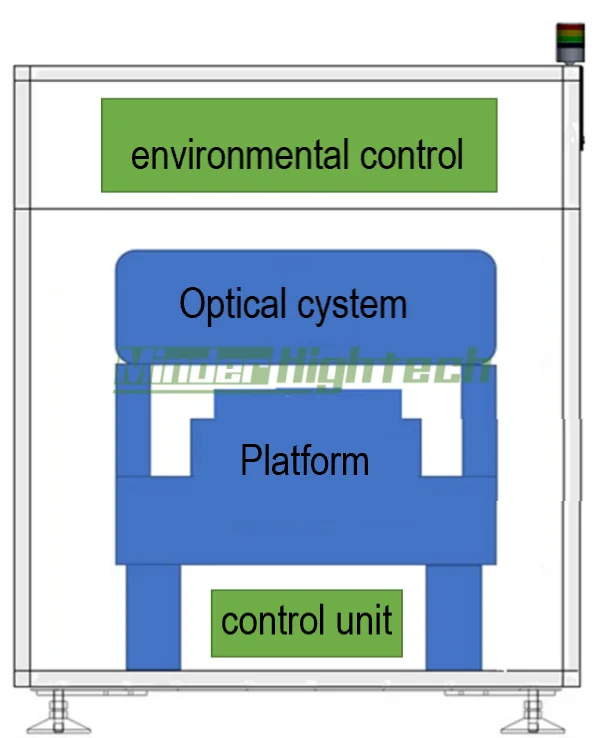

structure |

illustrate |

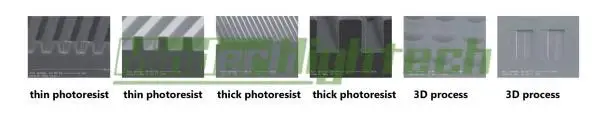

Exposing the countertop |

Exposure area: countertop, substrate placement area |

Optical system |

Laser emission molding area |

Environmental control system |

Control the internal temperature and positive pressure of the device |

Platform system |

Controls the movement of the exposure table to complete the operation of the exposure path |

Control system |

Control system of the entire equipment |

No. |

Environment |

Require |

1 |

Light source environment |

Yellow light |

2 |

Temperature |

22℃±2℃ |

3 |

Humidity |

50%±10% |

4 |

Cleanliness |

1000 |

5 |

CDA |

0.6±0.1Mpa,200LPM, dry, clean air |

6 |

Power supply |

220~240V、50/60Hz、2.5KW;The ground wire must be grounded, |

7 |

Cooling water |

Temp.:10℃~ 20℃ Pressure:0.3MPa ~ 0.5MPa Flow rate:20L/min Pressure difference:0.3MPa以上 Take over caliber:Rc3/8 |

8 |

Venue |

level:±3mm/3000mm shake:VC-B Bearing:750kg/㎡ |

10 |

Internet |

One network port |

11 |

Machine size |

1300*1100*2100mm |

12 |

Device weight |

1500kg |

No. |

Project |

Spec. |

Remark |

1 |

Resolution |

0.6um/or other requirement |

AZ703、AZ1350 |

2 |

CDU |

±10%@1um |

|

3 |

Substrate thickness |

0.2mm~4mm |

|

4 |

Date grid accuracy |

60nm |

|

5 |

Overlay |

±500nm |

130mmx130mm |

6 |

Stitching accuracy |

±200nm |

AZ703 |

7 |

MAX exposure size |

190X190mm |

|

8 |

Throughput |

≥300mm2/min |

≤50mj/cm2; |

9 |

light source |

LD 375nm |

|

10 |

light power |

6W |

|

11 |

Energy uniformity |

≥95% |

|

12 |

light life |

10000hr |

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved