UV light source center wavelength |

405nm |

Exposure uniformity |

More than 90% |

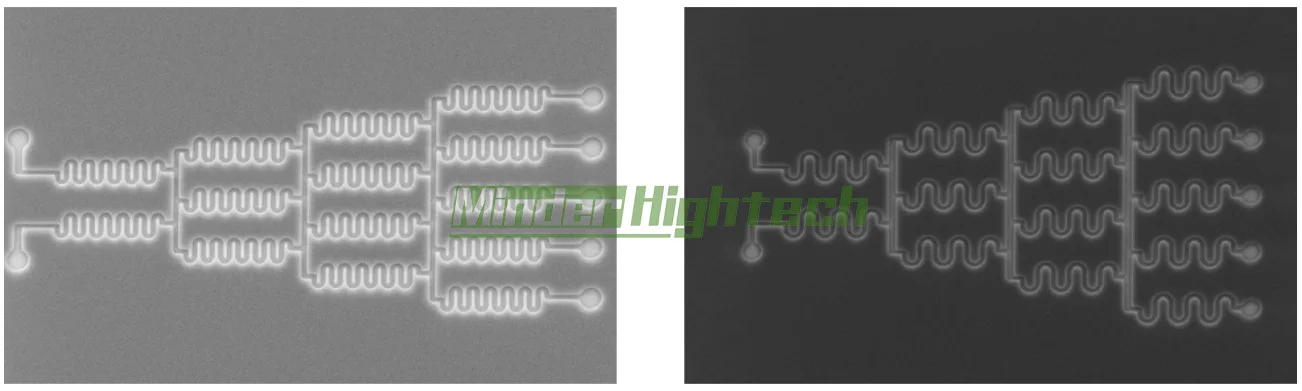

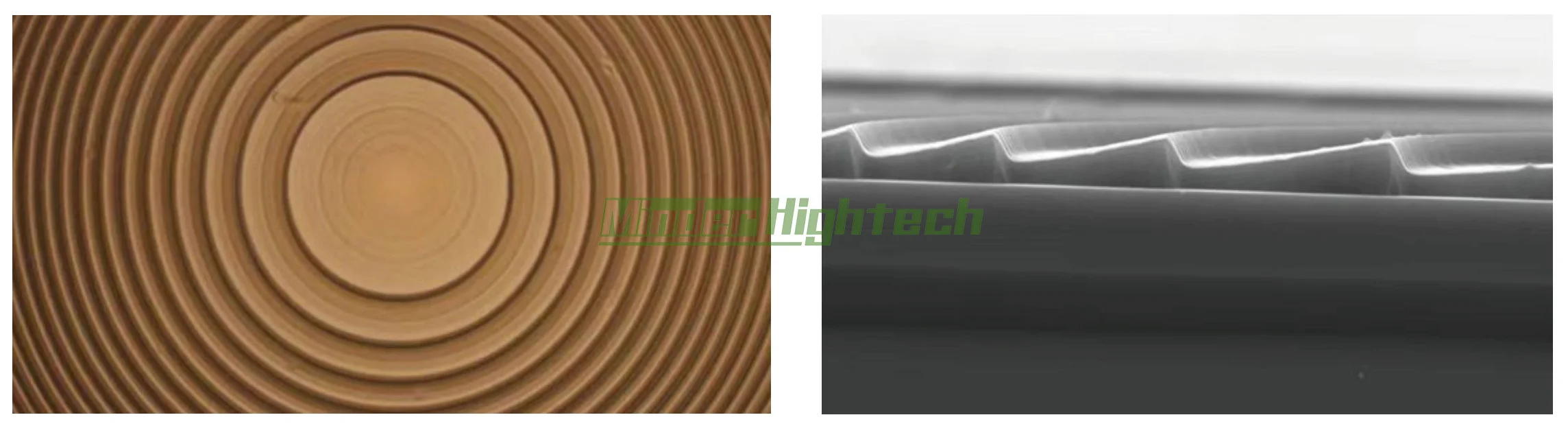

Minimum feature linewidth |

0.5um |

Single-pass writing field exposure area |

0.16*0.16mm (@0.5um) |

Writing speed |

80 mm²/min (1um feature line width) |

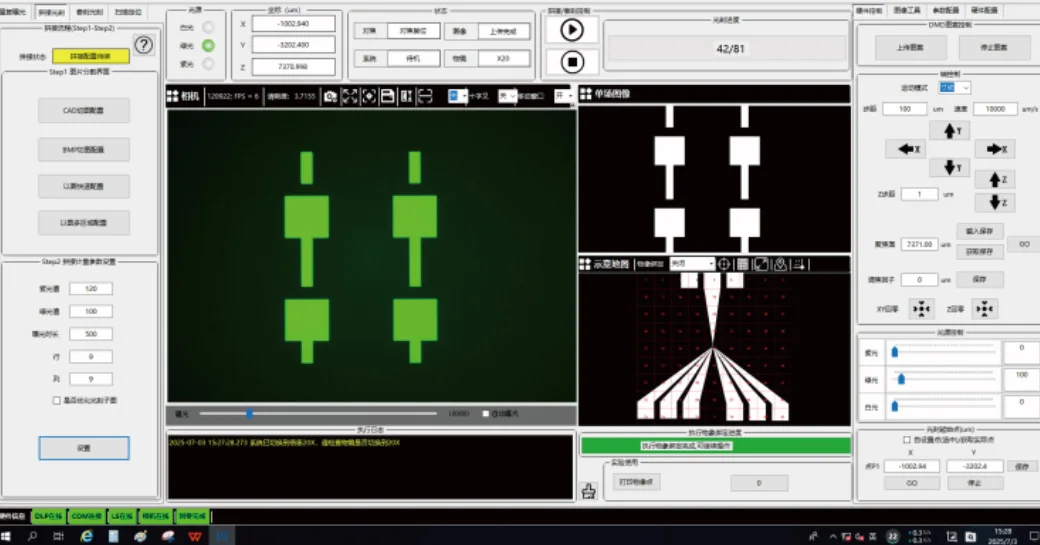

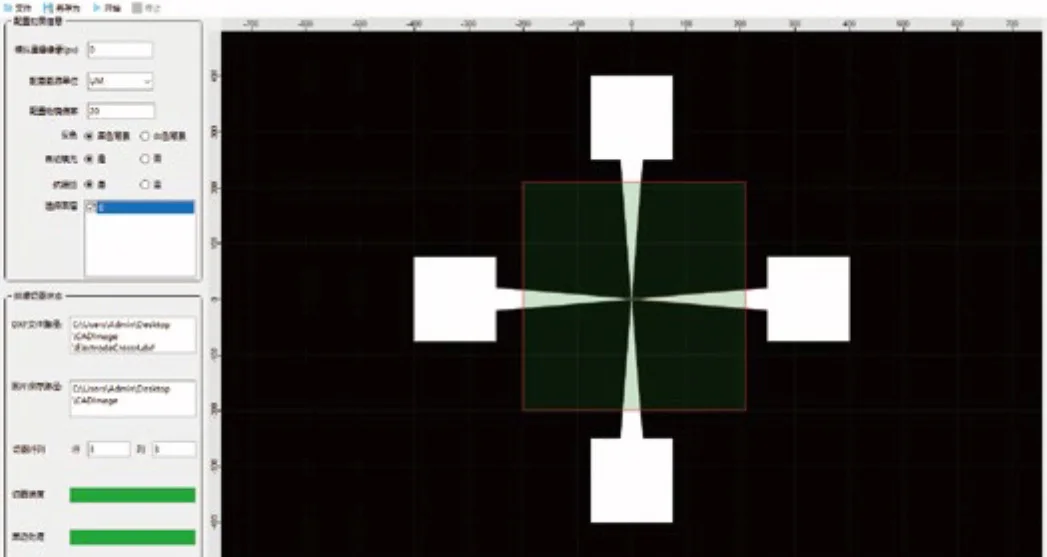

Supported image formats |

DXF, GDS, bmp, png, etc. |

Configuration |

Basic version |

Professional version |

|

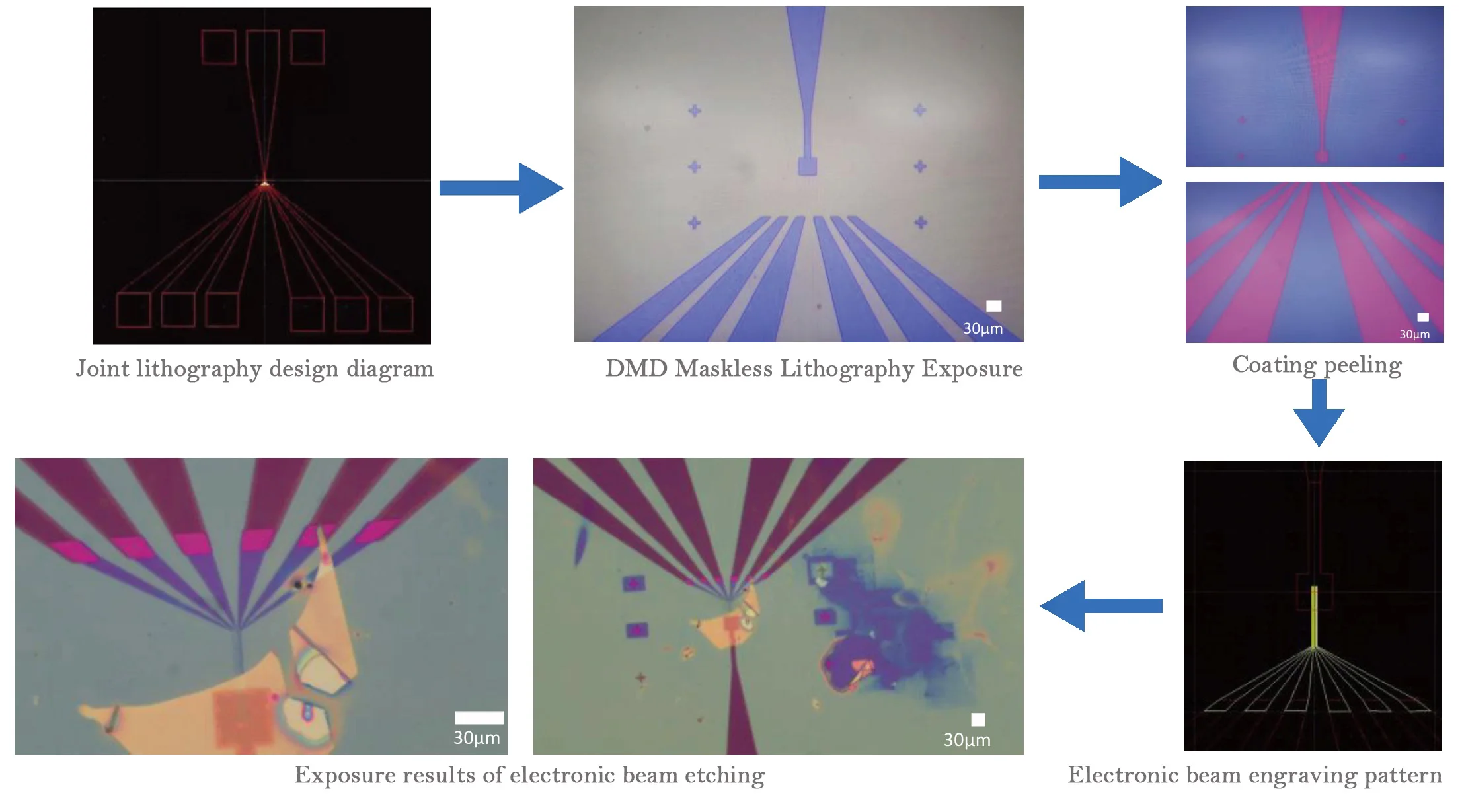

Light source |

High-power LED: 405nm |

||

DMD chip |

DLP6500 |

||

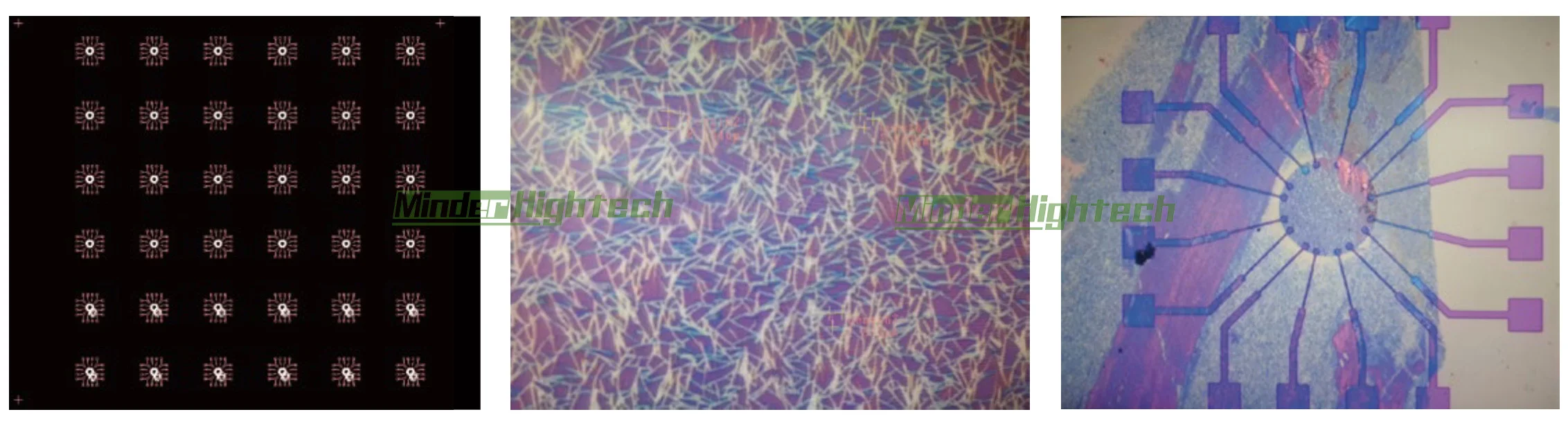

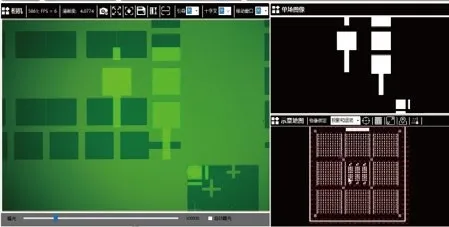

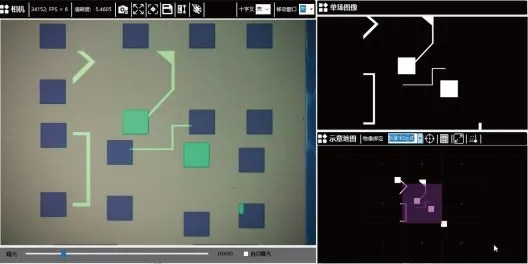

Single-field exposure area |

0.16*0.16mm (@0.5um), 0.4*0.4mm (@0.7um), 0.8*0.8mm (@1um), 1.6*1.6mm (@2um) |

||

Camera |

Large-area microscope camera (supports size measurement) |

||

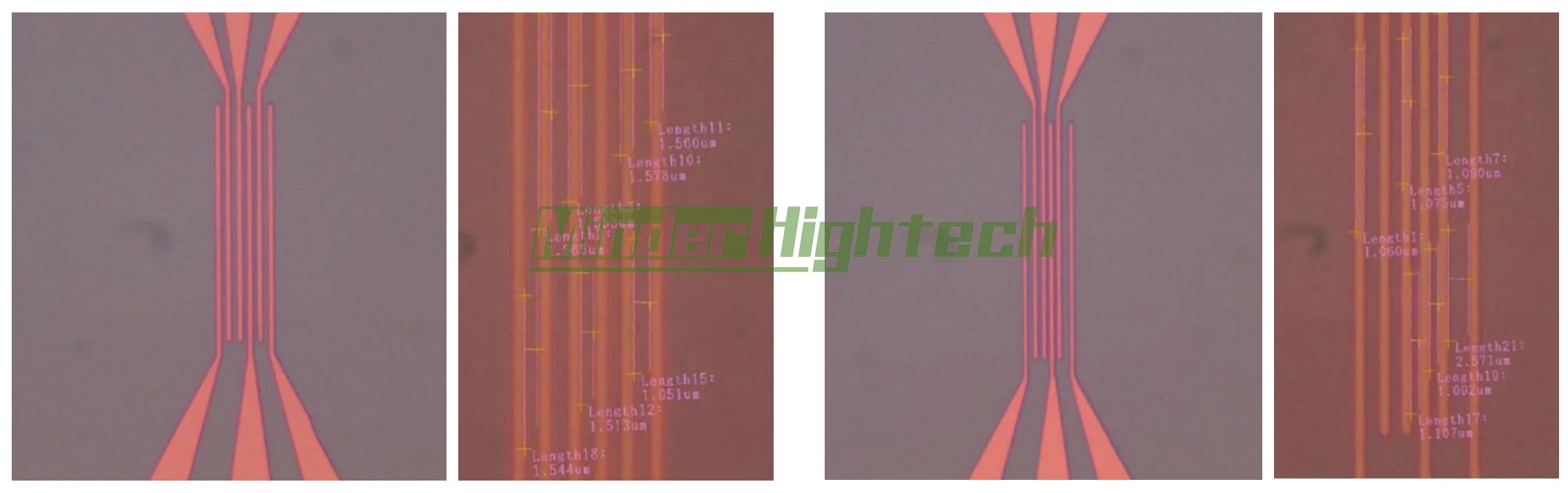

Minimum equidistant line width |

0.8 µm |

0.5μm |

|

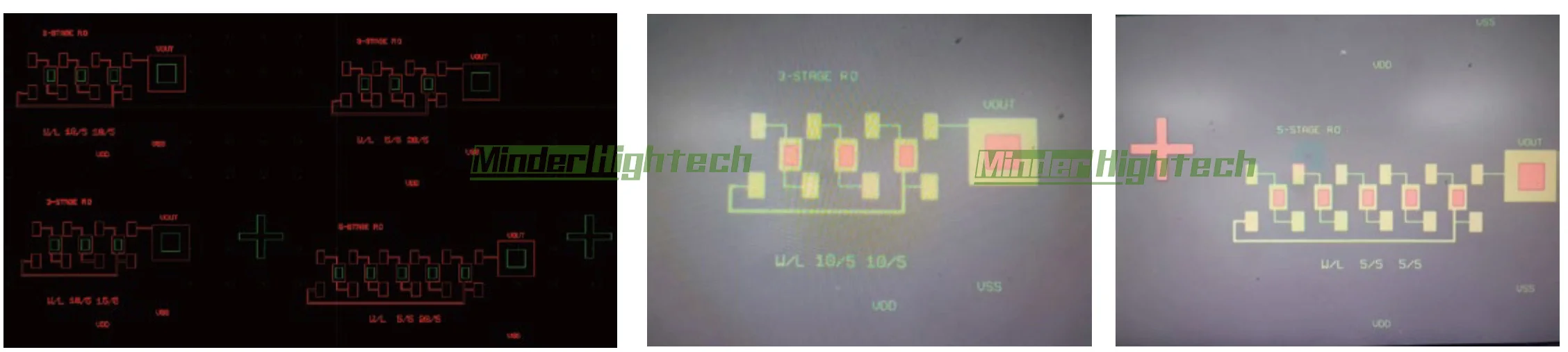

Stitching accuracy |

±0.3 µm |

±0.3μm |

|

Overlay accuracy |

±0.5 µm |

±0.5μm |

|

Writing speed |

20 mm²/min (1 µm feature linewidth) |

80 mm²/min (1μm feature linewidth) |

|

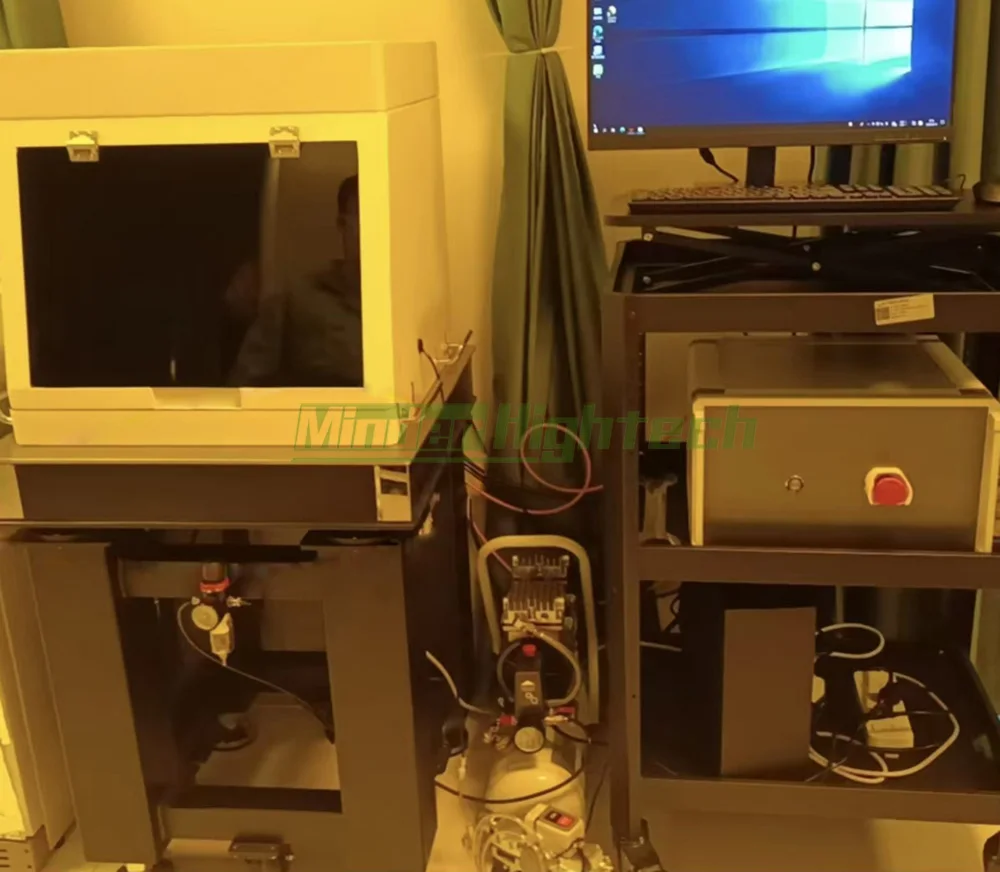

Motion stage |

High-precision linear motor (repeatable positioning accuracy ±0.25µm), leveling mechanism, manual rotary stage |

High-precision linear motor (repeatable positioning accuracy ±0.25µm), leveling mechanism, electric rotary stage |

|

Objective lens changer |

Manual objective lens switching |

Motorized objective lens switching |

|

Focusing module |

CCD image autofocus |

Laser active focusing |

|

Supported wafer sizes |

4 inch |

4-inch/8-inch |

|

Sample thickness |

0-10mm |

0-10 mm |

|

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved