Chip material |

Si and others |

Chip size |

0.3~30mm thickness:0.05 ~1.0 [mm] |

Supply methods |

2,4 Inch tray (waffle tray, gel-pak, metal tray etc) |

Substrate material |

SUS, Cu, Si, work piece, ceramic and others |

Tray amounts |

2inch tray up to 8, or 4inch tray up to 2;Tray can be freely set for chip or substrate. |

Substrate outer size |

15~50 [mm]& 8 [inch] wafer |

Substrate thickness |

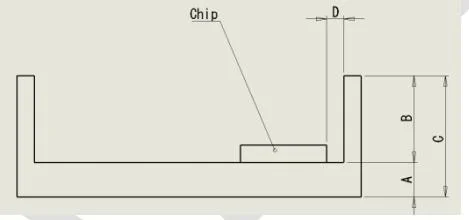

Flat shaped base plate 0.1~3.0[mm]; Tube shaped bottom plate:A:0.1~2[mm] B:≤5[mm],C:≤7[mm] The minimum distance from the chip to the inner wall of the can D: 21mm |

UPH |

Approx 12 [sec/cycle] [Conditions of cycle time] |

Z axis |

Resolution |

0.1[μ m] |

|

Movable range |

200[mm] |

||

Speed |

Max.250[mm/sec] |

||

θ axis |

Resolution |

0. 000225[°] |

|

Movable range |

±5[°] |

||

Chip holding |

Vacuum suction method |

||

Recipe change |

ATC (automatic tool changer) method Maximum number of jigs to be changed: 20x20[mm] 6 types *2 types when 30x30[mm] (option) is used. |

||

Set range |

Low load range:0.049 to 4.9[N](5 to 500[g]) High load range:4.9 to 1000[N](0.5 to 102[kg]) * Load control that covers both range is not possible. * Ultrasonic horn is only for high-load area |

Pressure accuracy |

Low load range: ±0.0098[N](1[g]) High load range: ±5[%](3σ) * Both accuracies are for RT actual load. |

Heating method |

Pulse heat method (Ceramic heater) |

Set temperature |

RT~450[°C] (1[°C] step) |

Temperature rising speed |

Max80[°C/sec] (without ceramic jig) |

Temperature distribution |

+5[°C] (30x30[mm] area) |

Cooling function |

With heat tool, work cooling function |

Oscillation frequency |

40[kHz] |

Vibration range |

Approximately 0.3 to 2.6[µ m] |

Heating method |

Constant heat method (ultrasonic horn) |

Set temperature |

RT~250[°C] (1[°C] step) |

Tool size |

M6 tool replacement types (screw in type) *Needs to change to the rigid type for more than 7x7[mm] chip size. |

Others |

Need to replace with pulse heat head. |

Mounting area |

50×50 [mm] |

Heating method |

Ceramic heater |

Set temperature |

RT~450[°C] (1[°C] step) |

Temperature distribution |

+5[°C] |

Temperature rising speed |

Max70[°C/sec] (without ceramic jig) |

Cooling function |

Available |

Work holding |

Vacuum suction method |

Recipe change |

Jig change |

XY stage |

Constant heater |

||

Stage for main bonding |

Mounting area |

200×200 [mm] (48 [inch] area) |

|

Heating method |

Constant heat |

||

Set temperature |

200×200 [mm]: RT to 250[°C] (1[°C] step) |

||

Temperature distribution |

±5% (200×200 [mm]) |

||

Work holding |

Vacuum suction method |

||

Recipe change |

Jig change |

||

Copyright © Guangzhou Minder-Hightech Co.,Ltd. All Rights Reserved