Regarding a vacuum eutectic reflow oven, the heating area and cavity height are information that are very important for higher production efficiency and reliable soldering process. Minder – Hightech technology and semiconductor/electronics expertise features the optimization of both heating area and cavity height to maximize productivity with consistent heating /soldering. Lets explore the defining characteristics of these Vacuum Package Line features and what they mean for precision machining in the industry.

Maximum Heating Zone and Cavity Height of Vacuum Eutectic Reflow Oven

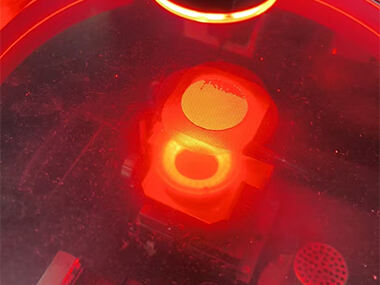

The heating region of a vacuum eutectic reflow oven is an area in the oven that contains one or more heaters for heating electrical devices. Large heating area enables more workpieces hot forming at the same time, which improved production efficiency. Minder-Hightech eutechtic reflow ovens are equipped with a large-size heating zone in order to allow uniform heating of many when soldering.

However, cavity 31 height is important in accommodating different sizes of electronic components. The cavity height affects the gap between the heating elements and components, affecting heating and soldering uniformity. Minder-Hightech’s High vacuum eutectic welding reflow ovens are available with variable cavity height enabling to handle parts of various dimensions and even form.

The Benefit of Large Heating Area for Good Production

A large heating area in a vacuum IR reflow oven has several benefits for productive production. The machine thus, first, permits a greater number of components to be treated per unit time, which results in shortened processing times and higher total product volumes. The manufacturing cycle time is reduced as more parts can be heated in the same operation.

In addition, a large heating area provides more even heat to the components, resulting in better and more uniform heating and soldering. The temperature of the heating region will then remain constant, thereby reducing possible defects as well as improving the overall quality of the soldered joints. The Vacuum Reflow Oven of Minder-Hightech has created the greatest heat capacity area to improve production rate and quality control.

Significance of Cavity Height to Achieving even Heat and Soldering

The height of cavity in a Eutectic Vacuum reflow oven is very important to have even heating and soldering of the electronic devices. The cavity height is suitable to give the required clearance between the elements and heating means, for an accurate control of soldering. Minder-Hightech knows that the cavity height is a critical issue to get reliable and reproducible solder joints and it plays an essential role.

Variable cavity heights on vacuum eutectic reflow ovens provide flexibility to work with a variety of sized and shaped device. This flexibility enables manufacturers to operate with a wide variety of electronic components yet not have to sacrifice soldering quality. By means of adjusting the cavity height, Minder-Hightech's reflow ovens in vacuum eutectic offer any kind of equably heating and therefore uniform soldering results for varied production needs.

Improving Efficiency with Ideal Heating Surface and Cavity Height

Because Minder-Hightech’s empty eutectic reflow ovens have adjustable cavity heights, they are also able to provide a larger heating area for other semiconductor and electronic manufacturing systems. Large heating space with high production efficiency by 2-4 times for its able to solder 100 components each time; Height of the welding is adjustable, ensuring even heat and flux.

Not only increase production, but also improve the heater area and hei ght pitch control. Strengthen the quality of products and reliability. The precise temperature control and even heating among all the parts can make solder joint with a high quality. Minder-Hightech vacuum eutectic reflow ovens are designed for the requirements of the up-to-date industrial electronic production, where emphasis is placed on efficient, high-quality and versatile operation.

Features of Our Wholesale Buyers' Vacuum Eutectic Reflow Oven

For the semiconductor and electronics industry wholesale clients we provide the leading up to date vacuum eutectic reflow ovens with features targeting efficient production. Our ovens have ample heating space for more components, batch processing and throughput. The adjustable height of the cavity permits even heating and soldering results, for a wide range of component sizes and forms.

Additionally, the Minder-Hightech Vacuum Eutectic Reflow Ovens feature high quality temperature control technology combined with powerful heater elements for superior results. Our dedication to quality and innovation distinguishes us as a dependable resource for wholesale purchasers in need of board fabrication & repair equipment, laser machines, consumables and adhesives for the electronics industry. Vacuum Eutectic Reflow ovens from Minder-HighTech allow wholesale buyers to take their productions and earnings to a new level, while also maintaining their competitive edge in today's industrial market.

Table of Contents

- Maximum Heating Zone and Cavity Height of Vacuum Eutectic Reflow Oven

- The Benefit of Large Heating Area for Good Production

- Significance of Cavity Height to Achieving even Heat and Soldering

- Improving Efficiency with Ideal Heating Surface and Cavity Height

- Features of Our Wholesale Buyers' Vacuum Eutectic Reflow Oven

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

IS

IS

HY

HY

AZ

AZ

KA

KA

/images/share.png)