Technical features:

1. Visual assisted positioning

The TO Fully Automatic Visual Sealing Machine is equipped with an advanced visual system, which can identify the welding target in real time and perform precise positioning to ensure the coaxiality of the chip light point and the tube cap, and improve welding efficiency and accuracy.

2. Automated welding

By adopting an automated control system, the TO fully automatic visual sealing machine can complete the welding task autonomously. The user only needs to set the welding parameters and target position, and the machine will automatically perform the welding operation without manual intervention. This greatly reduces the burden on the operator and improves production efficiency.

3. High-precision welding

The TO fully automatic visual sealing machine has excellent welding accuracy. Its precise welding technology and stable welding process can ensure the firmness and stability of the welding joint, and ensure the quality and consistency of welding.

4. Intelligent operation

The TO fully automatic visual sealing machine is equipped with an intelligent operation interface, which is easy to operate and easy to use. Users can complete parameter setting, task scheduling and monitoring operations through the touch screen and graphical interface. The intelligent operating system can monitor the welding process in real time, alarm and handle abnormal situations, and improve production safety.

Application areas:

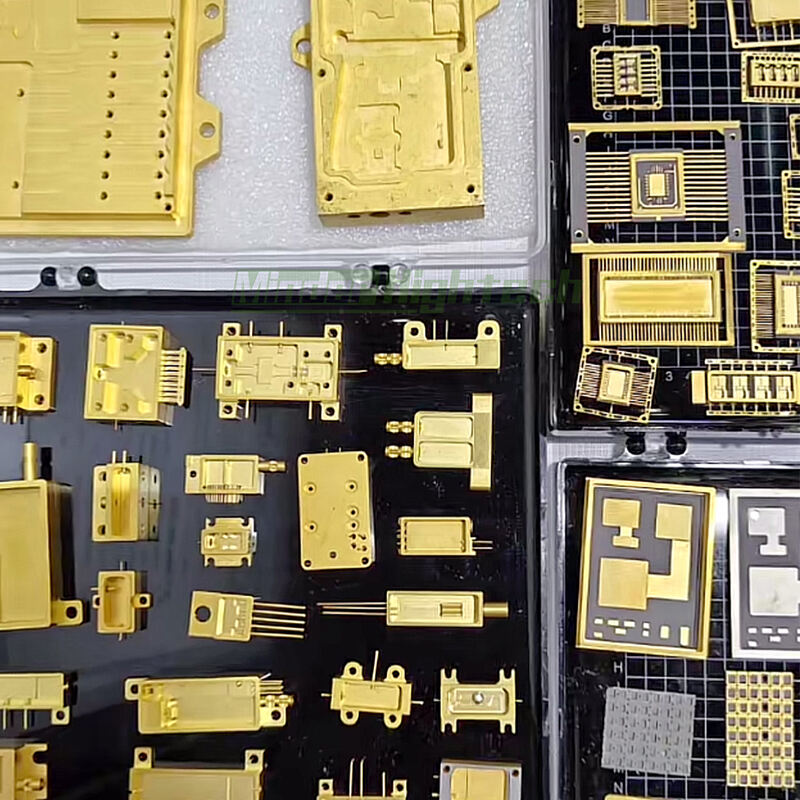

To Fully Automatic Visual Seal Welding Machine is widely used in various manufacturing industries, especially in areas that require high-precision and high-efficiency welding. The following are several typical application areas:

Optical communication industry: The welding quality and efficiency are also very high. TO fully automatic visual welding machine improves production efficiency and process level.

Sensor industry: TO fully automatic visual welding machine can provide customized welding solutions for different materials and welding requirements.

Electronic manufacturing industry: In the electronic manufacturing industry, the welding quality and efficiency of circuit boards and electronic components are required to be high. TO fully automatic visual welding machine can accurately weld electronic components and improve product stability and reliability.

Summarize:

The Fully Automatic Visual Seal Welding Machine is a high-efficiency welding equipment that integrates advanced technology and intelligent design. Its visual assisted positioning, automated welding, high-precision welding and intelligent operation make it an indispensable tool in modern manufacturing. Whether it is the electronics manufacturing industry, optical communication industry, or sensor industry, the T0 fully automatic visual welding machine can provide users with efficient, accurate and reliable welding solutions.

Using the TO fully automatic visual welding machine, enterprises can improve production efficiency, reduce costs, and further enhance product quality and market competitiveness.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

IS

IS

HY

HY

AZ

AZ

KA

KA

/images/share.png)