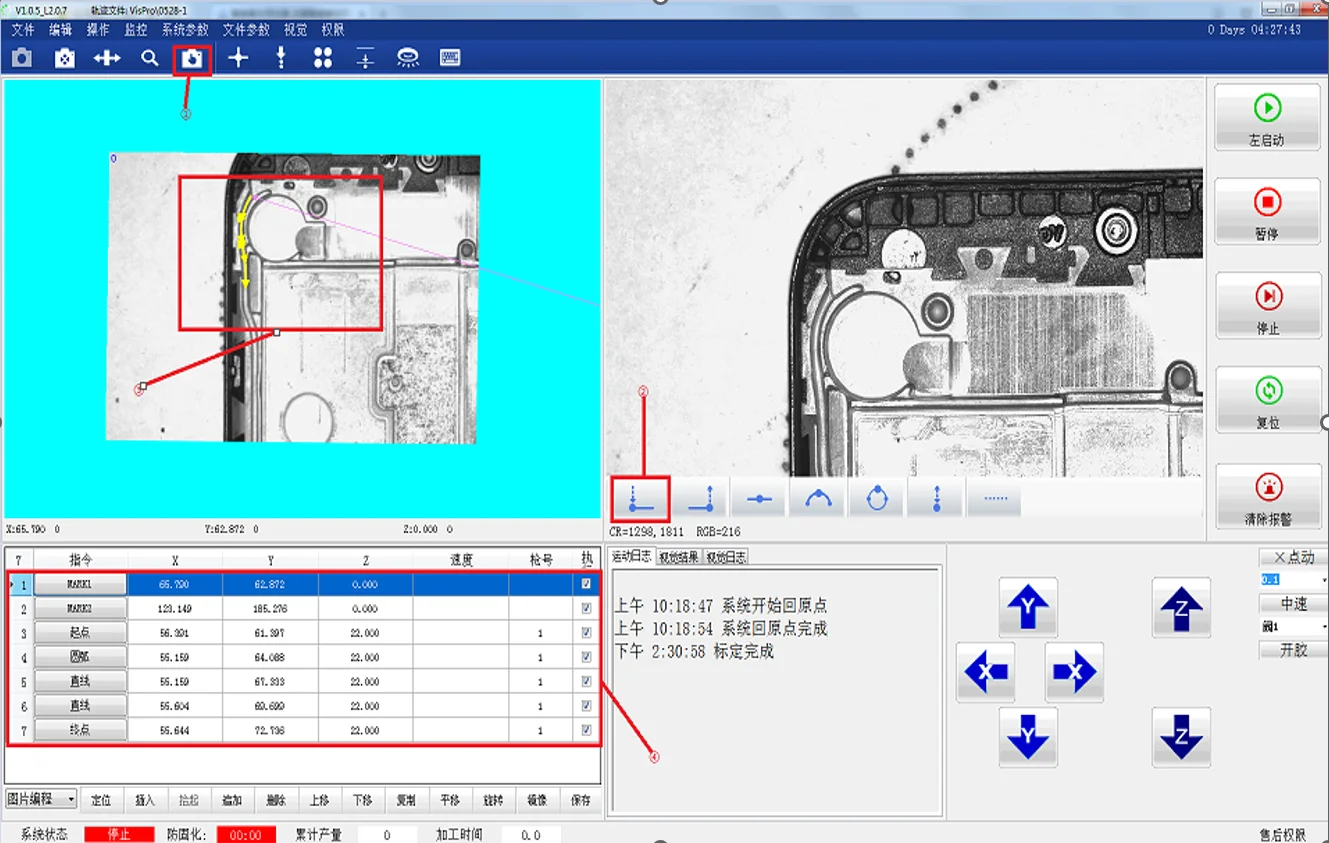

1. Supports multiple visual positioning and correction methods, including single MARK positioning, dual MARK positioning, triple MARK positioning, and local area positioning;

2. Supports various vision functions such as shape matching, circle matching, missing board detection, flying point detection, and on-the-fly image capture.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

IS

IS

HY

HY

AZ

AZ

KA

KA